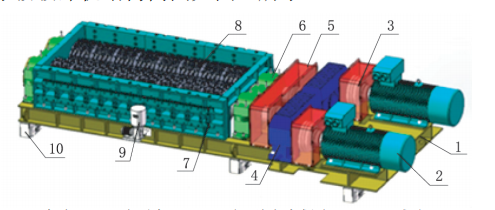

Sizing Crusher

SSC800 classification crusher consists of: 1. frame, 2. motor, 3. torque-limited hydraulic coupling, 4. reducer, 5. coupling, 6. bearing seat, 7. side plate, 8. crushing roller, 9. ubricating oil pump and 10. traveling mechanism.

1. Motor

As the power source of the classification crusher, the motor drives the crushing rollers of the classification crusher to run in opposite directions by generating driving torque. The classification crusher adopts flameproof three-phase asynchronous motor to ensure the safe and reliable operation of the crusher.

2. Torque-limiting hydraulic couple

In order to protect the motor of the classification crusher and change the rotation speed of the output shaft, the torque-limiting hydraulic coupling of the classification crusher uses liquid as the transmission medium to realize the connection between the motor and the active input shaft end and change the rotation speed of the output shaft.

3. Reducer

The main function of the reducer is to reduce the rotating speed, thus increasing the torque. According to the actual situation during the operation of the crusher, the graded crusher adopts planetary gear reducer, which has the advantages of high transmission efficiency and wide transmission ratio range, and can improve the efficacy of the crusher as a whole.

4. Drum tooth coupling

Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, in order to improve its bearing capacity and transmission efficiency, the drum gear coupling is selected. Compared with straight tooth coupling, drum tooth coupling has larger angular displacement compensation and larger transmission torque, effectively reducing tooth surface wear and noise, and prolonging service life.

5. Bearings

Bearings, as various structures supporting the crusher, bear the impact force brought by the crushing of raw coal and gangue, and reduce the mechanical load friction coefficient of the crusher during transmission. The performance of bearings is directly related to the normal operation and working efficiency of the crusher. The self-aligning roller bearing selected by the classification crusher has two rows of rollers, which can bear multi-directional axial load and has higher radial load force, and can meet the operation requirements of the classification crusher under heavy load or vibration load conditions.

6. Crush tooth roll

In order to improve the crushing efficiency of the crusher, At the same time, the over-crushing rate is reduced. The classification crusher adopts a double-tooth roller crushing design. Raw coal and gangue entering the classification crusher are brought into the tooth roller meshing area through the crushing teeth on the two pairs of tooth rollers. Lump coal reaching the crushing standard is brought into forced crushing, while lump coal not reaching the standard falls from the crushing teeth to realize classification crushing.

7. Walking mechanism

In order to facilitate the movement of the graded crusher during overhaul, the sliding of the copper shaft and the shaft sleeve is designed to realize the movement of the equipment.

8. Rack

As the foundation of the graded crusher, the frame should also meet the high-strength load brought by the operation of the crusher.