Briquetting.Mixing.Grinding.Drying.HBI.RHF

Luoyang Kaizheng Environmental Protection Processing Equipment Co., Ltd is a collection of product research and development, manufacturing, independent trade high-tech enterprises. We have been focusing on developing integrated solutions for raw material preparation, ingredients, solid waste, residual materials and recycled materials to help customers more efficiently process various materials and convert them into value. Innovation of mixing machine, high pressure briquetting machine, grinding with roller press and other equipment in solving all kinds of industrial materials. Processing equipment with high viscosity in solvent recovery, evaporation, and other industries have unique applications. Compaction granulating device in all kinds of the comprehensive utilization of solid waste and other process is also significant.

-

05-02-2025

On January 18, 2025, Luoyang Kaizheng Environmental Protection Technology Equipment Co., Ltd. held ten ceremonies and New Year party in Marriott Hotel. This event is not only a review and summary of the company's development in the past ten years, but also a prospect and expectation for the bright future.

-

22-01-2025

Against the backdrop of global climate change, China is actively seeking ways to reduce carbon dioxide emissions in order to achieve the strategic goals of carbon neutrality and carbon compliance. In this context, the application of H2/coal based reduction technology in the field of refractory mineral processing and smelting is leading a new technological revolution.

-

16-12-2024

In the great journey of striving towards carbon peak in the industrial field, environmental protection process equipment such as ball rollers, mixers, compaction granulators, cold and hot pressing technologies have become the core driving force for promoting green transformation in key industries. This series of actions not only demonstrates the power of technological innovation, but also embodies a profound commitment to efficient resource utilization and environmental protection.

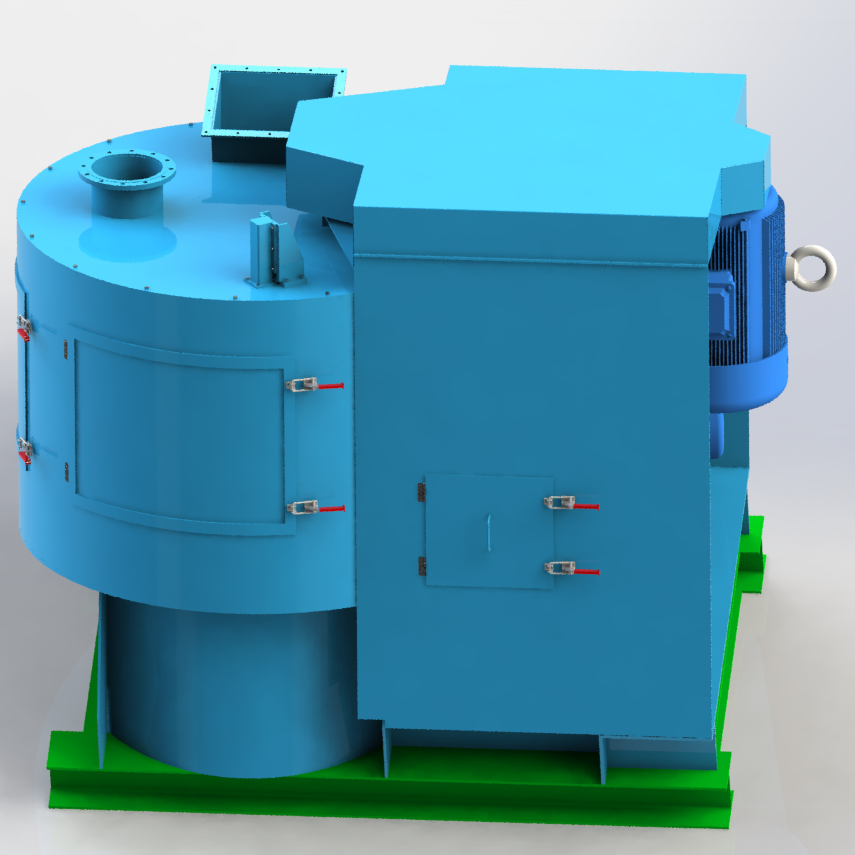

Vertical High Intensity Mixer

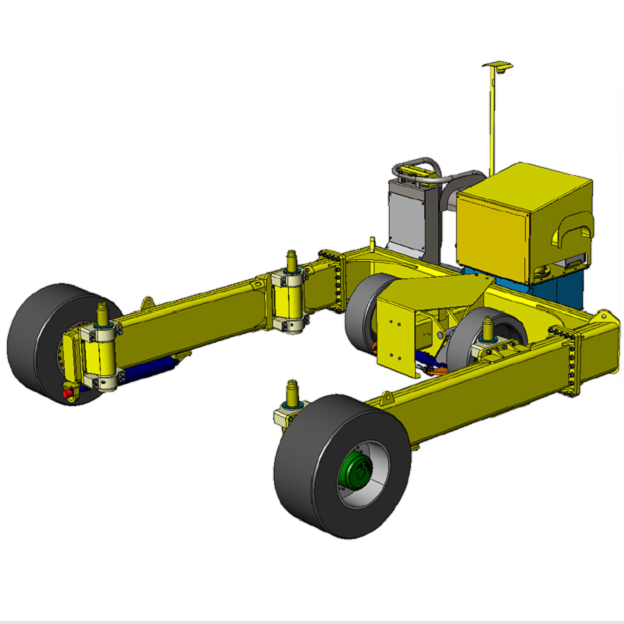

Feed Chute Transporter

Sludge Silo

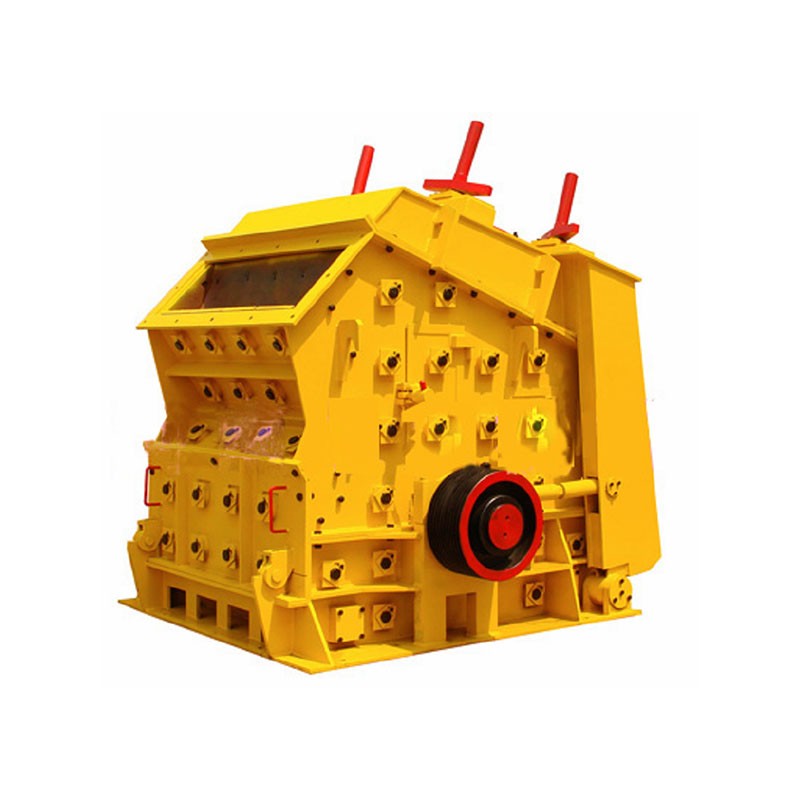

Impact Crusher

Double Toothed Crusher

Jaw Crusher

Vertical Dryer

Net Belt Dryer

Twin-shaft Kneaderreactor

Shear Mixer

Pin Mixer

Horizontal Mixer

Twin-shaft Mixer

Lab Scale Briquetting

Sponge Iron Briquetting

Sponge Iron

Grinding Roller Press

Granulating Machine

Briquetting Machine

High Pressure Briquetting