Oil Sludge Thermal Desorption Technology

Oil Sludge Thermal Desorption Technology

Technology Background: The Necessary Choice Under Environmental Pressure

Oilfield sludge is a complex hazardous waste containing petroleum hydrocarbons, heavy metals, and chemicals. Traditional methods like landfill and incineration have drawbacks such as land occupation, resource waste, or secondary pollution (e.g., dioxins), failing to meet increasingly stringent environmental standards. Consequently, developing a technology capable of "volume reduction, harmless treatment, and resource recovery" for sludge is urgently needed. Thermal desorption technology has emerged as a key solution to this industry challenge due to its unique advantages.

Core Technology: Efficient and Clean Process Principle

The core of thermal desorption technology involves heating oil sludge to a medium-high temperature range of 450-550°C through indirect heating in an oxygen-free or anaerobic environment. Under these conditions, petroleum substances in the sludge do not combust but instead evaporate and undergo thermal cracking, separating from the solid particles.

This technology offers three major outstanding advantages:

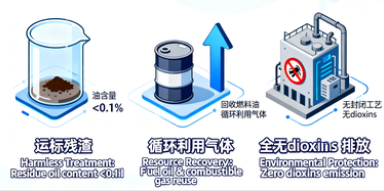

Thorough Harmless Treatment: Treated solid residue can achieve a stabilized oil content of below 0.1%, far exceeding national standards and achieving complete detoxification of hazardous waste.

Adequate Resource Recovery: Volatilized oil and gas are condensed and recovered as fuel oil, enabling resource reuse. The generated non-condensable combustible gases can be recycled as system fuel, reducing operational energy consumption.

Minimal Environmental Impact: The fully enclosed process without open flame combustion prevents the generation of highly toxic substances like dioxins from the source. Exhaust gases are treated for clean emission.

Engineering Practice: Kaizheng Environmental Solutions

Luoyang Kaizheng Environmental Protection Equipment Co., Ltd. has successfully transformed this advanced technology into mature and reliable packaged equipment. Its core product, the "LYKZ Series Intelligent Thermal Desorption System", provides effective solutions to key challenges in engineering applications:

Core Reactor Technology: Employs a unique indirectly heated screw conveyor structure. This design ensures continuous and uniform material feeding while its powerful mixing and shearing force effectively breaks down sludge caking barriers, guaranteeing efficient heat transfer and operational stability.

Intelligent Control System: Integrates a PLC/DCS automated control system for precise monitoring and control of key parameters like temperature, pressure, and feed rate, significantly reducing manual operation intensity and errors, and ensuring stable treatment results and long-term, safe equipment operation.

Energy Cycle Optimization: The system innovatively incorporates a waste heat recovery network and enables purification and reuse of non-condensable gases, establishing an efficient internal energy cycle that drastically reduces reliance on external fuel and enhances operational economy.

Processing Performance Evidence: Leveraging its optimized process and reliable equipment, the sludge residue treated by the Kaizheng system consistently achieves an oil content stably below 0.1%, not only meeting environmental requirements but also creating possibilities for residue resource utilization (e.g., brick making, road subbase).

Summary and Outlook

Thermal desorption technology is currently the ideal solution for treating oilfield oil sludge, perfectly aligning with the concept of a green circular economy. Luoyang Kaizheng Environmental Protection Equipment Co., Ltd., as an outstanding practitioner in this field, provides customers with efficient, economical, and stable integrated solutions through its solid engineering expertise and continuous equipment innovation. Their successful applications fully demonstrate the significant practical value and promotion potential of thermal desorption technology in the oilfield environmental sector, offering robust technical equipment support for advancing the green and sustainable development of the petroleum industry. In the future, as the technology continues to evolve and upgrade, thermal desorption is destined to play an increasingly important role in the environmental protection field.