Hydrogen-Ammonia Industry Booms: China Leads the Zero-Carbon New Landscape

Accelerated Implementation of "Chemical Industry Progress" Research Achievements, Hundred-Billion-Yuan Projects Drive Cross-Industry Decarbonization

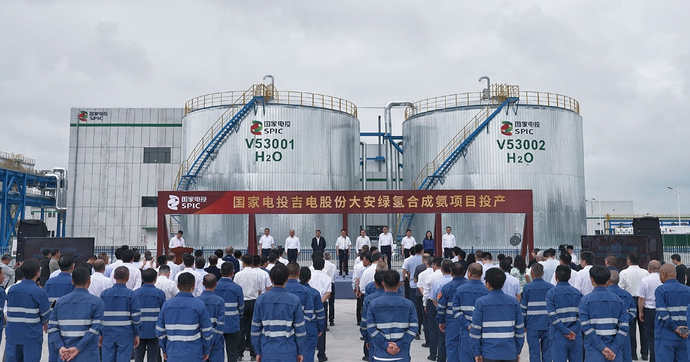

As the "green hydrogen-to-ammonia (H2A) - green ammonia-to-hydrogen (A2H)" cycle model proposed in the paper "Research Progress and Prospects of Hydrogen-Ammonia Green Cycle" published in the journal "Chemical Industry Progress" continues to be implemented, China's hydrogen-ammonia green energy industry is experiencing explosive growth. Recently, a series of major developments have emerged one after another: Goldwind Science & Technology plans to invest approximately 18.92 billion yuan in a wind power-to-hydrogen, ammonia and methanol project, the first phase of Envision's Chifeng 1.52 million-ton green ammonia project has been put into production, and Jidian Co., Ltd.'s Da'an green ammonia project has set four global records. These milestones mark that this emerging track, which can solve the problem of hydrogen storage and transportation and promote the decarbonization of traditional industries, has moved from the laboratory to large-scale commercial operation.

The core logic of the hydrogen-ammonia green cycle is to produce green hydrogen through water electrolysis driven by renewable energy, then synthesize green ammonia with nitrogen for energy storage and long-distance transportation, and finally provide zero-carbon energy for industries such as chemical engineering, steel and transportation through green ammonia-to-hydrogen technology or direct conversion technology. This model not only subverts the high-energy-consuming and high-emission ammonia synthesis path of the traditional Haber-Bosch process, but also builds a full-chain zero-carbon ecosystem of "green electricity - green hydrogen - green ammonia", becoming a key link connecting renewable energy and traditional industries. Research in "Chemical Industry Progress" points out that breakthroughs in core technologies such as medium-low temperature/room temperature ammonia synthesis and efficient green ammonia decomposition are the core driving forces for industrial scaling.

Supported by technological breakthroughs, China's hydrogen-ammonia integration projects present a pattern of "joint efforts by state-owned enterprises and private enterprises, and simultaneous development on land and sea". On land, provinces rich in wind and solar resources such as Inner Mongolia, Jilin and Xinjiang have become industrial highlands: Envision's Chifeng project, as the world's largest green hydrogen-ammonia project, pioneered the 100% direct green electricity connection and full dynamic operation mode. Through the EnOS intelligent Internet of Things system, it realizes the dynamic adaptation between the fluctuation of wind and solar power generation and ammonia synthesis production. An ammonia tank worth 150 million yuan can store the energy equivalent to 100 million kilowatt-hours of electricity, with an energy storage cost only 1/400 of that of traditional battery energy storage. Jidian Co., Ltd.'s Da'an project has achieved an annual carbon dioxide emission reduction of 650,000 tons through four world-leading technologies including alkaline-PEM hybrid water electrolysis for hydrogen production and DC microgrid. Its green ammonia products have obtained EU low-carbon certification and are exported overseas. Marine exploration has also started. The first domestic offshore hydrogen-ammonia-methanol integration project jointly built by National Energy Group and CIMC Raffles has entered the commissioning stage, providing a new path for offshore wind power consumption.

Behind the industrial boom is the combined drive of multiple strategic values. According to incomplete statistics, there are currently more than 800 signed and registered green hydrogen-ammonia-methanol projects in China, with the planned total production capacity of green methanol approaching 60 million tons per year. The participating entities include central enterprises such as National Energy Group and Sinopec, as well as private enterprises such as Goldwind Science & Technology and Envision Energy. Such projects can not only solve the problem of renewable energy consumption through a flexible model of "production matching the power grid", but also provide practical zero-carbon solutions for hard-to-decarbonize industries such as shipping and steel. As a zero-carbon fuel that can be liquefied at room temperature and pressure, green ammonia has strong compatibility with existing storage and transportation facilities and has become the preferred solution for shipping decarbonization. Envision's Chifeng project has signed a long-term procurement agreement with Marubeni Corporation of Japan, and the first batch of green ammonia from Jidian's Da'an project has been shipped to European, Japanese and South Korean markets.

Despite the broad industrial prospects, challenges such as technical stability and cost control mentioned in "Research Progress and Prospects of Hydrogen-Ammonia Green Cycle" still need to be addressed. Currently, the price of green ammonia, which exceeds 800 US dollars per ton, still has a premium compared with gray ammonia, and issues such as technical coupling efficiency and green premium sharing mechanism remain to be improved. However, the industry generally optimistic about its development potential: with the continuous decline in wind and solar power generation costs and the advancement of localization of equipment such as electrolyzers, the China Hydrogen Energy Alliance predicts that when the hydrogen price drops to 12-15 yuan per kilogram, green ammonia will realize large-scale substitution of gray ammonia.

Industry experts said that the hydrogen-ammonia green cycle has become one of the core tracks for China's energy transition, and 21 provinces (autonomous regions and municipalities directly under the Central Government) have included it in their local government work reports. In the future, with the further maturity of technologies such as medium-low temperature ammonia synthesis catalysts and efficient green ammonia decomposition, as well as the improvement of the carbon trading market, this "green petroleum" industry will leverage a trillion-level zero-carbon economic market and provide a replicable "China plan" for global energy transition.