Analysis of the Characteristics of Bio-Coal Briquettes from Agricultural and Coal Industry Waste (2)

3. Results and Discussion

The object of research is the characteristics of briquettes, including the characteristics of combustion. Table 2 presents the results of the analysis of briquettes from sunflower husks and coal dust from the Karazhyra deposit.

Table 2.The results of the analysis of briquettes (sunflower husk and Karazhyra coal dust).

| No. | Briquette Composition SH/CD1, % | Particle Size | Density (kg/m3) | Strength (%) | Moisture (%) | Ash (%) | Volatile Matter, (%) | Calorific Value, (kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| SNI | - | - | - | ≤8% | ≤8% | ≤15% | ≥20,950 | |

| 1 | 80/20 | 0–2 | 869.26 | 83.84 | 4.00 | 5.04 | 38.07 | 21,166.83 |

| 2 | 70/30 | 0–2 | 901.48 | 80.95 | 4.60 | 6.09 | 38.75 | 21,337.71 |

| 3 | 60/40 | 0–2 | 958.62 | 75.31 | 5.00 | 8.03 | 40.26 | 22,106.61 |

| 4 | 50/50 | 0–2 | 1000.91 | 69.27 | 6.50 | 9.88 | 40.85 | 23,045.00 |

| 5 | 40/60 | 0–2 | 1047.98 | 66.46 | 7.20 | 10.42 | 41.96 | 23,644.40 |

| 6 | 30/70 | 0–2 | 1079.54 | 64.09 | 7.50 | 11.87 | 42.18 | 24,675.23 |

| 7 | 80/20 | 3–6 | 865.97 | 71.13 | 4.50 | 5.31 | 34.80 | 20,464.00 |

| 8 | 70/30 | 3–6 | 872.25 | 71.07 | 5.00 | 6.83 | 36.60 | 20,989.36 |

| 9 | 60/40 | 3–6 | 903.93 | 68.49 | 5.60 | 8.86 | 37.56 | 22,028.00 |

| 10 | 50/50 | 3–6 | 932.14 | 66.24 | 6.00 | 10.38 | 38.98 | 22,810.00 |

| 11 | 40/60 | 3–6 | 947.34 | 63.58 | 6.50 | 11.70 | 40.12 | 23,292.37 |

| 12 | 30/70 | 3–6 | 966.54 | 61.38 | 7.20 | 12.63 | 41.67 | 24,374.00 |

SH = Sunflower husk, CD1 = Coal dust (Karazhyra).

Table 2 shows that the moisture content of the obtained samples does not exceed 7.5%, the ash content lies in the range from 5.04 to 12.63%, the calorific value ranges from 20,464.0 kJ/kg to 24,413.3 kJ/kg, and volatile matter are in the range from 38.07% to 42.18%. The high yield of volatile matter negatively affects the duration of combustion and is associated with the specifics of the plant materials used.

Table 3 presents the results on the burning rate, burning time, and ignition of briquettes from sunflower husks and coal dust from the Karazhyra deposit.

Table 3.The results of burning rate, burning time, and ignition (sunflower husk and Karazhyra coal dust).

| No. | Briquette Composition SH/CD1 (%) | Particle Size (mm) | Burning Rate (g/s) | Burning Time (min) | Ignition Time (s) |

|---|---|---|---|---|---|

| 1 | 80/20 | 0–2 | 0.00196 | 34.00 | 16 |

| 2 | 70/30 | 0–2 | 0.00115 | 58.13 | 16 |

| 3 | 60/40 | 0–2 | 0.00074 | 90.00 | 16 |

| 4 | 50/50 | 0–2 | 0.00073 | 91.67 | 16 |

| 5 | 40/60 | 0–2 | 0.00072 | 93.11 | 18 |

| 6 | 30/70 | 0–2 | 0.00071 | 93.40 | 20 |

| 7 | 80/20 | 3–6 | 0.00551 | 12.09 | 8 |

| 8 | 70/30 | 3–6 | 0.00434 | 15.36 | 10 |

| 9 | 60/40 | 3–6 | 0.00386 | 17.28 | 12 |

| 10 | 50/50 | 3–6 | 0.00320 | 20.85 | 18 |

| 11 | 40/60 | 3–6 | 0.00198 | 33.68 | 20 |

| 12 | 30/70 | 3–6 | 0.00124 | 53.78 | 23 |

The results showed that the briquettes of this composition showed good values in terms of combustion characteristics. The Indonesian National Standard (SNI) was used for the comparison since there is no national standard for briquettes in the Republic of Kazakhstan.

The composition of the bio-coal briquette and the particle size of the mixture affect the main characteristics of the fuel briquette. A finer fraction (0–2 mm) leads to better characteristics in terms of strength, ash content, calorific value, and burning time in the absence of a binder in the briquette. Briquettes of a fine fraction compared to briquettes of a coarse fraction have a longer burning time (about three times longer) and a lower burning rate. For all briquettes, with an increase in the composition of coal dust, the burning time increases, and the burning rate decreases. This can be explained as when briquettes burn with a finer fraction, the effect of compacting their structure can be seen. Consequently, the denser briquettes burn longer at a lower burning rate. The content increase in the coal fraction in the briquette leads to decline of a volatile yield (Table 3 and Table 4). As ignition conditions deteriorate, the burning rate decreases and increases the total time of the briquette burning. The ignition time of these briquettes is small (within 23 s). It should be noted that the shorter the ignition period, the better the combustion process of the fuel briquette will be.

Table 4. The results of the analysis of briquettes (sunflower husk and Shubarkul coal dust).

| No. | Briquette Composition SH/CD1, % | Particle Size | Density (kg/m3) | Strength (%) | Moisture (%) | Ash (%) | Volatile Matter, (%) | Calorific Value, (kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| SNI | - | - | - | ≤8% | ≤8% | ≤15% | ≥20,950 | |

| 1 | 80/20 | 0–2 | 895.28 | 73.14 | 5.50 | 3.86 | 37.11 | 21,087.81 |

| 2 | 70/30 | 0–2 | 918.70 | 72.18 | 5.95 | 4.77 | 37.81 | 21,878.25 |

| 3 | 60/40 | 0–2 | 1033.57 | 71.54 | 6.42 | 5.27 | 38.02 | 23,144.61 |

| 4 | 50/50 | 0–2 | 1040.19 | 70.63 | 6.53 | 6.58 | 38.67 | 23,799.24 |

| 5 | 40/60 | 0–2 | 1053.40 | 67.39 | 6.90 | 7.22 | 39.00 | 25,201.40 |

| 6 | 30/70 | 0–2 | 1070.46 | 65.28 | 7.50 | 8.79 | 39.60 | 26,005.54 |

| 7 | 80/20 | 3–6 | 885.09 | 68.25 | 5.00 | 4.23 | 33.56 | 20,983.00 |

| 8 | 70/30 | 3–6 | 905.39 | 67.02 | 5.22 | 5.21 | 34.88 | 21,675.98 |

| 9 | 60/40 | 3–6 | 936.13 | 66.27 | 5.47 | 6.5 | 36.01 | 23,007.12 |

| 10 | 50/50 | 3–6 | 993.58 | 65.86 | 5.50 | 7.18 | 36.70 | 23,452.10 |

| 11 | 40/60 | 3–6 | 972.35 | 64.72 | 5.97 | 8.16 | 37.65 | 24,796.38 |

| 12 | 30/70 | 3–6 | 1022.51 | 62.29 | 6.50 | 9.15 | 38.20 | 25,814.68 |

SH = Sunflower husk, CD2 = Coal dust (Shubarkul).

The most optimal ratio was the ratio of a mixture of 70% sunflower husk and 30% coal dust with the following characteristics: humidity 4.6%, ash content 6.09%, volatile matter 38.75%, and calorific value 21,337.71 kJ/kg.

Table 4 presents the results of the analysis of briquettes from sunflower husks and coal dust from the Shubarkul deposit.

Table 5 presents the results on the burning rate, burning time, and ignition of briquettes from sunflower husks and coal dust from the Shubarkul deposit.

Table 5. The result of burning rate, burning time and ignition (sunflower husk and Shubarkul coal dust).

| No. | Briquette Composition SH/CD1 (%) | Particle Size (mm) | Burning Rate (g/s) | Burning Time (min) | Ignition Time (s) |

|---|---|---|---|---|---|

| 1 | 80/20 | 0–2 | 0.00114 | 58.27 | 14 |

| 2 | 70/30 | 0–2 | 0.00082 | 81.78 | 15 |

| 3 | 60/40 | 0–2 | 0.00076 | 88.12 | 18 |

| 4 | 50/50 | 0–2 | 0.00070 | 95.87 | 18 |

| 5 | 40/60 | 0–2 | 0.00061 | 108.60 | 20 |

| 6 | 30/70 | 0–2 | 0.00058 | 115.38 | 20 |

| 7 | 80/20 | 3–6 | 0.00551 | 76.25 | 12 |

| 8 | 70/30 | 3–6 | 0.00482 | 77.50 | 14 |

| 9 | 60/40 | 3–6 | 0.00434 | 79.26 | 14 |

| 10 | 50/50 | 3–6 | 0.00386 | 81.48 | 15 |

| 11 | 40/60 | 3–6 | 0.00320 | 85.90 | 18 |

| 12 | 30/70 | 3–6 | 0.00198 | 98.57 | 22 |

In this case, as in the previous version, a finer fraction of the mixture (0–2 mm) gives better characteristics in terms of strength, calorific value, and combustion parameters.

The results of the analysis show that these briquettes have good performance in terms of moisture content, ash content, calorific value, and combustion parameters. It should be noted that the ash content is lower than in the previous case and meets the requirements for bio-coal briquettes. Briquettes from 60% sunflower husk and 40% coal dust from the Shubarkul deposit showed the best characteristics compared to other compositions of this type of briquettes.

Table 6 and Table 7 present the results of the analysis of briquettes from sunflower husks and coke dust.

Table 6. The results of the analysis of briquettes (sunflower husk and coke dust).

| No. | Briquette Composition SH/CD1, % | Particle Size | Density (kg/m3) | Strength (%) | Moisture (%) | Ash (%) | Volatile Matter, (%) | Calorific Value, (kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| SNI | - | - | - | ≤8% | ≤8% | ≤15% | ≥20,950 | |

| 1 | 80/20 | 0–2 | 995.85 | 86.10 | 5.24 | 2.98 | 30.17 | 20,449.46 |

| 2 | 70/30 | 0–2 | 1061.57 | 84.15 | 5.12 | 3.45 | 28.52 | 20,849.99 |

| 3 | 60/40 | 0–2 | 1065.38 | 78.20 | 4.70 | 4.01 | 25.33 | 21,867.93 |

| 4 | 50/50 | 0–2 | 1123.25 | 71.34 | 4.52 | 4.28 | 23.25 | 22,577.16 |

| 5 | 40/60 | 0–2 | 1169.96 | 68.16 | 4.17 | 4.64 | 20.15 | 23,086.95 |

| 6 | 30/70 | 0–2 | 1225.27 | 66.59 | 4.09 | 5.11 | 18.65 | 23,995.62 |

| 7 | 80/20 | 3–6 | 856.78 | 85.30 | 3.87 | 3.35 | 27.84 | 20,344.66 |

| 8 | 70/30 | 3–6 | 860.31 | 83.45 | 3.63 | 3.59 | 25.64 | 20,685.23 |

| 9 | 60/40 | 3–6 | 897.38 | 74.60 | 3.56 | 4.24 | 23.57 | 21,589.36 |

| 10 | 50/50 | 3–6 | 1054.33 | 63.61 | 3.38 | 4.78 | 21.76 | 22,406.21 |

| 11 | 40/60 | 3–6 | 1164.91 | 57.32 | 3.29 | 4.92 | 18.75 | 22,899.74 |

| 12 | 30/70 | 3–6 | 1207.84 | 56.28 | 3.23 | 5.64 | 16.69 | 23,708.99 |

SH = Sunflower husk, CD = Coke dust.

Table 7. The result of burning rate, burning rime and ignition (sunflower husk and coke dust).

| No. | Briquette Composition SH/CD1 (%) | Particle Size (mm) | Burning Rate (g/s) | Burning Time (min) | Ignition Time (s) |

|---|---|---|---|---|---|

| 1 | 80/20 | 0–2 | 0.001107 | 60.20 | 18 |

| 2 | 70/30 | 0–2 | 0.001040 | 64.11 | 19 |

| 3 | 60/40 | 0–2 | 0.000880 | 75.78 | 20 |

| 4 | 50/50 | 0–2 | 0.000800 | 83.33 | 22 |

| 5 | 40/60 | 0–2 | 0.000752 | 88.68 | 22 |

| 6 | 30/70 | 0–2 | 0.000690 | 96.67 | 24 |

| 7 | 80/20 | 3–6 | 0.001699 | 39.23 | 12 |

| 8 | 70/30 | 3–6 | 0.001358 | 49.09 | 14 |

| 9 | 60/40 | 3–6 | 0.000950 | 70.17 | 15 |

| 10 | 50/50 | 3–6 | 0.000900 | 74.07 | 16 |

| 11 | 40/60 | 3–6 | 0.000859 | 77.64 | 18 |

| 12 | 30/70 | 3–6 | 0.000800 | 83.33 | 22 |

Moisture content of briquettes from sunflower husk and coke dust does not exceed 5.24%, ash content is in the range of 5.64%, volatile matter is in the range from 16.69% to 30.17%, and the calorific value is in the range from 20,344.66 kJ/kg to 23,995.62 kJ/kg. The results showed that in this case too, a finer fraction of the mixture (0–2 mm) gives better characteristics in terms of strength, calorific value, and burning time. Briquettes from 70% sunflower husk and 30% coke dust with an ash content of 3.45%, moisture content 5.12%, density 1061.57 kg/m3, volatile matter yield 28.52%, calorific value 20,849.99 kJ/kg, time ignition 19 s, and burning time 64.11 min showed good combustible and strength qualities compared to other compositions of this type of briquettes.

Table 8 and Table 9 present the results of the analysis of briquettes from leaves and coal dust from the Karazhyra deposit.

Table 8. The results of the analysis of briquettes (leaves and Karazhyra coal dust).

| No. | Briquette Composition SH/CD1, % | Particle Size | Density (kg/m3) | Strength (%) | Moisture (%) | Ash (%) | Volatile Matter, (%) | Calorific Value, (kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| SNI | - | - | - | ≤8% | ≤8% | ≤15% | ≥20,950 | |

| 1 | 80/20 | 0–2 | 1116.95 | 97.24 | 4.50 | 8.33 | 25.46 | 23,241.79 |

| 2 | 70/30 | 0–2 | 1151.12 | 96.45 | 5.50 | 9.32 | 28.07 | 23,478.12 |

| 3 | 60/40 | 0–2 | 1170.16 | 95.26 | 6.00 | 11.00 | 30.80 | 24,111.34 |

| 4 | 50/50 | 0–2 | 1177.92 | 94.78 | 7.00 | 12.01 | 32.68 | 24,546.12 |

| 5 | 40/60 | 0–2 | 1222.60 | 93.61 | 7.40 | 13.11 | 35.80 | 24,704.58 |

| 6 | 30/70 | 0–2 | 1224.96 | 92.56 | 8.50 | 14.42 | 37.50 | 25,415.67 |

L = Leaves, CD1 = Coal dust (Karazhyra).

Table 9. The result of burning rate, burning time and ignition (leaves and Karazhyra coal dust).

| No. | Briquette Composition SH/CD1 (%) | Particle Size (mm) | Burning Rate (g/s) | Burning Time (min) | Ignition Time (s) |

|---|---|---|---|---|---|

| 1 | 80/20 | 0–2 | 0.00066 | 101.50 | 20 |

| 2 | 70/30 | 0–2 | 0.00064 | 104.00 | 16 |

| 3 | 60/40 | 0–2 | 0.00061 | 109.23 | 16 |

| 4 | 50/50 | 0–2 | 0.00056 | 120.00 | 18 |

| 5 | 40/60 | 0–2 | 0.00044 | 152.13 | 20 |

| 6 | 30/70 | 0–2 | 0.00043 | 154.33 | 16 |

The results of the analysis of briquettes from leaves and coal dust of the Karazhyra deposit showed that the main characteristics of these briquettes basically correspond to the criteria for biofuel briquettes. The humidity of the obtained briquettes does not exceed 8.5%, volatile matter are in the range from 25.46% to 37.50%, the calorific value is in the range from 23,241.79 kJ/kg to 25,415.67 kJ/kg. These values are good indicators of biofuel briquettes. It should be noted that the ash content of these briquettes ranges from 8.33% to 14.42%, which is slightly higher than the requirements of the standard, but much lower than the ash content of coal currently used in small boilers and in private households. The burning time of briquettes from leaves significantly exceeds the corresponding indicators of briquettes from sunflower husks. The increase in burning time is associated with a higher content of lignin in the leaves and a higher density of the briquette.

Briquettes of a composition of 80% leaves and 20% coal dust with an ash content of 8.30%, humidity 4.50%, density 1116.95 kg/m3, volatile matter yield 25.46%, calorific value 23,241.79 kJ/kg, time ignition 20 s, and burning time 101.50 min showed the best combustible and strength properties compared to other compositions of this type of briquettes.

Table 10 and Table 11 present the results of the analysis of briquettes from leaves and coal dust from the Shubarkul deposit.

Table 10. The results of the analysis of briquettes (leaves and Shubarkul coal dust).

| No. | Briquette Composition SH/CD1, % | Particle Size | Density (kg/m3) | Strength (%) | Moisture (%) | Ash (%) | Volatile Matter, (%) | Calorific Value, (kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| SNI | - | - | - | ≤8% | ≤8% | ≤15% | ≥20,950 | |

| 1 | 80/20 | 0–2 | 1272.60 | 98.64 | 4.50 | 7.42 | 24.58 | 21,863.27 |

| 2 | 70/30 | 0–2 | 1280.34 | 97.35 | 4.68 | 8.02 | 26.31 | 22,905.68 |

| 3 | 60/40 | 0–2 | 1297.05 | 96.43 | 5.00 | 8.24 | 29.00 | 23,498.19 |

| 4 | 50/50 | 0–2 | 1339.65 | 95.81 | 5.60 | 9.30 | 30.68 | 24,657.70 |

| 5 | 40/60 | 0–2 | 1348.57 | 94.69 | 6.00 | 9.86 | 32.70 | 25,807.69 |

| 6 | 30/70 | 0–2 | 1358.16 | 93.95 | 6.40 | 10.40 | 34.60 | 26,520.60 |

L = Leaves, CD2 = Coal dust (Shubarkul).

Table 11. The result of burning rate, burning time, and ignition (leaves and Shubarkul coal dust).

| No. | Briquette Composition SH/CD1 (%) | Particle Size (mm) | Burning Rate (g/s) | Burning Time (min) | Ignition Time (s) |

|---|---|---|---|---|---|

| 1 | 80/20 | 0–2 | 0.00097 | 68.48 | 16 |

| 2 | 70/30 | 0–2 | 0.00091 | 73.23 | 16 |

| 3 | 60/40 | 0–2 | 0.00081 | 81.91 | 18 |

| 4 | 50/50 | 0–2 | 0.00076 | 87.78 | 18 |

| 5 | 40/60 | 0–2 | 0.00052 | 128.65 | 18 |

| 6 | 30/70 | 0–2 | 0.00038 | 175.00 | 18 |

The results of the analysis showed that the main characteristics of these briquettes also meet the criteria for biofuel briquettes. The moisture content of the obtained briquettes does not exceed 6.4%, the ash content ranges from 7.42% to 10.40%, volatile matter ranges from 24.58% to 34.60%, and the calorific value ranges from 21,863.27 kJ/kg up to 26,520.60 kJ/kg. Briquettes from 70% leaves and 30% coal dust with an ash content of 8.02%, moisture content 4.68%, density 1280.34 kg/m3, volatile matter output 26.31%, calorific value 22,905.68 kJ/kg, ignition time 16 s, and burning time 73.23 min showed good combustible and strength properties in comparison with other compositions of this type of briquettes. The ash content in this case is somewhat higher than the standardized values, but much less than the ash content of coal, which makes briquettes of this composition less environmentally harmful.

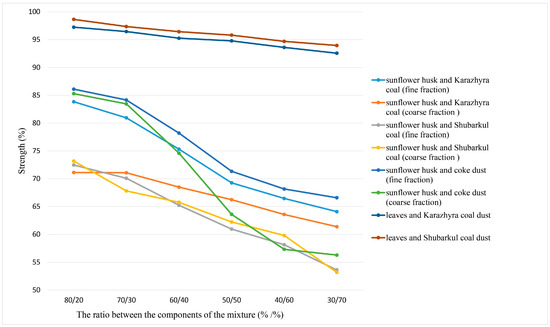

It should be noted that the strength of briquettes is one of the essential characteristics of this type of fuel. In the studied bio-coal briquettes, the strength is largely determined by the composition (the ratio between the components of the mixture).

Figure 1 shows that with an increase in the content of coal or coke dust in the briquette, the strength decreases. Moreover, for briquettes from sunflower husks and coarse coke dust, the decrease in strength is the most significant compared to other mixtures. Briquettes from leaves and coal dust showed the highest strength in the entire range of ratios. This is due to the high content of natural binder (lignin) in the leaves. In the remaining briquettes, the absence of a binder affected the strength of the final product. However, for some ratios of husks and coal dust, or coke dust, the strength values are quite high (70–85%).

Figure 1.The dependence of the strength of the briquette on the ratio between the components of the mixture.

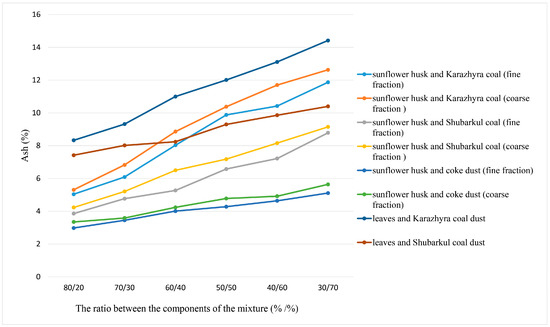

It is known that the ash content of a bio-coal briquette determines its environmental efficiency. Therefore, this indicator was analyzed with a change in the type and ratio of the components of the bio-coal mass (Figure 2).

Figure 2. Change in ash content depending on the type and ratio of the components of the bio-coal mass.

The nature of the change in the ash content of the briquette is the same for different types and compositions of bio-coal raw materials: with a decrease in the biomass content, the ash content will increase. The reason is the different initial ash content of the mixture components.

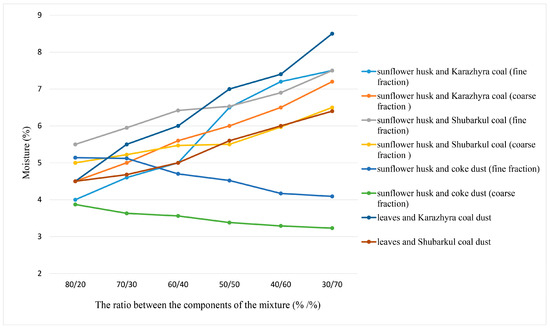

Figure 3 shows the nature of the change in the moisture content of the obtained bio-coal briquettes. It can be argued that for briquettes from sunflower husks, leaves, and coal dust, the moisture content increases with the increase in the content of coal dust in the mixture. For briquettes from husks and coke dust, this characteristic behaves differently: with an increase in the content of coke dust, the humidity decreases. This is due to the lower moisture content in coke dust than in coal.

Figure 3. The dependence of the moisture content of briquettes on the type and ratio of the components of the bio-coal mass.

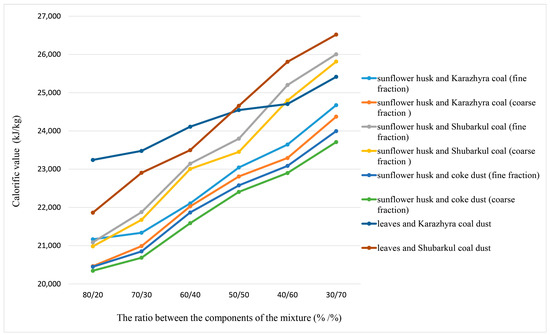

The most important characteristic of any briquette as a fuel is its calorific value. Taking this into account, the change in heat generation during the combustion of briquettes was studied depending on the type and ratio of components (Figure 4). The calorific value of all studied bio-coal briquettes showed good values (from 20,449.46 to 26,520.60 kJ/kg). The briquettes from leaves and coal showed the best value. Even the minimum content of coal and coke dust (20%) gives a good result in terms of calorific value.

Figure 4. Change in the calorific value of briquettes depending on the type and ratio of the components of the mixture.

The obtained values showed that the studied bio-coal briquettes have good thermal properties. Therefore, they can be used as a source of heat generation at a local level, thereby reducing dependence on coal as a source of heat generation. The briquetting process is viable for converting biowaste into fuel for small scale energy and domestic use in an affordable and efficient manner. This process is economical, cheap, environmentally friendly, and affordable, and it can be used by housing and communal services, farms, as well as rural residents in various regions of the country.

The required pressing pressure in the production of the developed fuel briquettes without a binder is at least 25 MPa. According to the technical characteristics of briquetting presses manufactured by Gemco Energy, ABC Machinery and others, the average cost of electrical energy for briquetting is from 45 to 60 kWh per 1 ton of briquettes.

The sufficient strength of the developed briquettes allows them to be produced in a briquetting press without any heating. The absence of energy costs for heating in the briquette press allows for a reduction in electric power consumption by 25–30%. Considering the low price of electricity in the Republic of Kazakhstan, such as USD 0.12 per kilowatt-hour in the city of Pavlodar [33], the production of fuel briquettes is feasible in terms of electricity expenses.

It should also be noted that the characteristics of bio-coal briquettes containing leaves significantly depend on the characteristics of the raw material (leaves): place, time, method of collection, etc.

4. Conclusions and Future Research Direction

In this work, the authors analyzed bio-coal briquettes from biomass and industrial waste. The study offered a solution to the problem associated with disposal of sunflower waste and leaf litter. Local raw materials (sunflower husks and leaves) in combination with coal and coke dust are suitable as an alternative source of fuel. Characteristics of the investigated bio-coal briquettes, such as density, strength, moisture content, ash content, volatile yield, calorific value, ignition time, ignition duration, and burning rate have quite good values. The characteristics of the studied briquettes demonstrated that the best in terms of strength, calorific value and combustion parameters are 70% of sunflower husk and 30% of coal dust from the Karazhyra deposit; 60% of sunflower husk and 40% of coal dust from the Shubarkul deposit; briquettes from 70% of sunflower husk and 30% of coke dust; briquettes from 80% of leaves and 20% of coal dust from the Karazhyra deposit; and briquettes from 70% of leaves and 30% of coal dust from the Shubarkul deposit. Briquettes from a fine fraction compared to briquettes from a coarse fraction have a threefold longer burning time and a lower burning rate. For all briquettes, with an increase in the composition of coal dust, the burning time increases, and the burning rate decreases. The resulting briquettes ignite faster, emit a sufficient amount of heat with a significant calorific value, are denser, and more durable. Briquetting technology has great potential for converting biowaste into fuel for use in an affordable and efficient manner. This process is economical, environmentally friendly, cheap and therefore affordable, and can be used by small boiler houses, housing and municipal services, farms, and residents in rural areas. The absence of a binder in the composition of the briquettes decreases the cost of bio-coal briquettes. Bio-coal briquettes can be used as a source of fuel on a local level, thus reducing dependence on coal as a source of heat generation.

The obtained results make a possibility to continue research in this direction. Future research will focus on the efficiency of using bio-coal briquettes from sunflower husks, leaves mixed with coal and coke dust in small boilers. The authors plan to study the issues of economic analysis of the use of these bio-coal briquettes as fuel, as well as to investigate the environmental aspects of burning these briquettes.

Nikiforov, A., Kinzhibekova, A., Prikhodko, E., Karmanov, A., & Nurkina, S. Analysis of the Characteristics of Bio-Coal Briquettes from Agricultural and Coal Industry Waste. Energies, 16(8), 3527. https://doi.org/10.3390/en16083527