Application of high-strength aluminum iron briquette

As one of the main deoxidizers in steelmaking process, Al-Fe alloy has strong deoxidizing and purifying effects, which can improve the morphology of inclusions and reduce the content of gas elements in molten steel. However, the requirements for aluminum-ferroalloy are very high and strict in terms of production technical standards and quality. Due to the complex production process, high energy consumption, high pollution and the improvement of environmental protection requirements in the production of aluminum-iron alloy by medium frequency induction furnace, its application space is gradually reduced. In order to ensure the stable and continuous supply of aluminum-ferroalloy, various steel mills are looking for new aluminum deoxidizers to replace aluminum-ferroalloy. Through market research, it is found that aluminum products will produce a large amount of dust and debris in the production process, which can be recycled. Mixing with iron powder according to a certain proportion to make its chemical composition basically consistent with aluminum-iron alloy. Through extrusion molding, it has high density, high falling strength, easy storage, environmental protection and energy saving, and can be used as a new aluminum deoxidizer.

1. Process

The production process of high-strength aluminum-iron pressing ball mainly includes:

(1) Aluminum powder and iron powder are proportioned according to a certain ratio. Then mix evenly, and the total amount of mixture is 1 ton each time.

(2) Conveying the mixture to the intermediate silo, and uniformly feeding the mixture to the ball pressing machine by the screw feeder for extrusion molding.

(3) Crushing the formed pressure ball, then lifting it to a rotary screen for screening, returning the screen blanking to a silo for recycling, and the screen material is the finished high-strength aluminum-iron pressure ball.

The particle size and composition of the high-strength aluminum-iron pressing ball obtained by the method are basically the same as those of the aluminum-iron alloy, and the production process is simple, thus overcoming the defects of high energy consumption and high pollution in the previous production process. The raw materials of high-strength aluminum-iron pressing ball are mostly secondary utilization resources and the price is low.

2. Contrast test

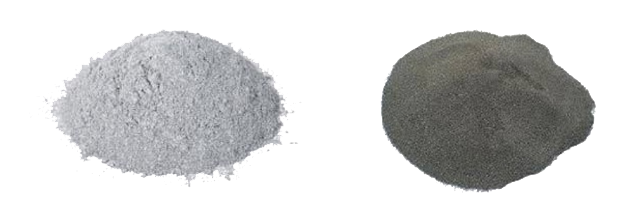

Test raw materials: The raw materials for the production of high-strength aluminum-iron pressing balls are aluminum powder and iron powder, with high purity and low magazine element content.

The test quantity is 50t, and the materials are fed in four times, 10t, 10t, 15t and 15t respectively. During the four feeding processes, the head and tail of the belt and the blanking port are monitored by special personnel, mainly observing whether there is any crushing and pulverization phenomenon during the material feeding process. Finally, the high-strength aluminum-iron pressing ball is added to the steel flow after half of the converter tapping.

3. Outcome discussion

3.1 Comparison of Alloy Consumption

The increase of alloy usage will not only increase the cost, but also affect the temperature drop, increase the amount of slag and the introduction of impurity elements. Therefore, the usage of alloy should be paid more attention to in the replacement of alloy.

3.2 Comparison of Deoxygenation Capacity

The main function of high-strength aluminum-iron pressing ball and aluminum-iron alloy is to remove excess oxygen from molten steel. Its deoxidation ability directly affects the element yield and is one of the important indexes to evaluate the amount of deoxidation alloy.

3.3 Tapping Temperature Comparison

Since aluminum deoxidizer is mainly an endothermic reaction in converter, the temperature drop caused by alloy use is not conducive to the quality of molten steel. The temperature drop fluctuation of the high-strength aluminum-iron pressure ball is smaller, which is conducive to accurate prediction of the tapping temperature on site. Under the condition of ensuring smooth pouring, the tapping temperature is effectively reduced, the molten steel quality is improved, and the smelting cost is reduced.

4. Conclusion

(1) The raw materials for the production of high-strength aluminum-iron pressing balls are cheap and the process is simple. It has basically the same chemical composition and the particle size is basically the same as that of aluminum-iron alloy. Compared with the traditional aluminum-titanium alloy, the high-strength aluminum-iron pressing ball overcomes the defects of high energy consumption and large pollution in the process of producing aluminum-iron alloy by medium frequency induction furnace. It is a new type of aluminum-containing composite deoxidizer that saves energy, reduces emissions and realizes greening.

(2) Through tests, the usage amount, deoxidization capacity and tapping temperature drop of high strength aluminum-iron alloy are basically the same. In the tapping process, adding high-strength aluminum-iron pressing balls does not generate smoke and dust, thus reducing the environmental protection pressure on site.

(3) The purchase price of high-strength aluminum-iron pressing balls is lower than that of aluminum-iron alloy in the same period, resulting in remarkable economic benefits. On the premise that the strength and moisture content meet the production requirements, increasing the usage of high-strength aluminum-iron pressing balls can effectively reduce the cost per ton of steel.