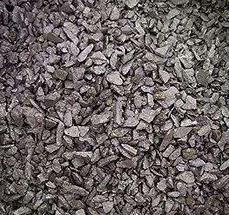

High-carbon ferrochromium ash Briquetting

A ferroalloy company produces high-carbon ferrochromium. Each submerged arc furnace is equipped with a negative pressure bag dust removal system to collect and treat the flue gas and dust in the submerged arc furnace. The content of chromium in the dust removal ash of high-carbon ferrochromium is about 7%. Due to the certain toxicity of Cr6 +, the current treatment method of the enterprise is to directly add it to the burden for re-smelting. Secondary dust and pollution are produced in the long-distance conveying process of belt system, which will affect the air permeability of burden when added to submerged arc furnace, and chromium element can not be well utilized, resulting in waste of resources. It is one of the effective utilization methods of dust removal ash to use high-carbon ferrochrome dust briquettes as raw materials for high-carbon ferrochrome production. Through the implementation of this technology, the recycling of chromium element in dust removal ash of high-carbon ferrochromium is realized, the hidden danger of environmental protection is eliminated, and the economic benefit of high-carbon ferrochromium production is improved.

Analysis of dust composition

The content of the Cr element in high carbon ferrochromium dust ash reaches 6.88%, which has a certain recycling value. The direct addition of dust ash to the burden for re-smelting will seriously affect the air permeability of the smelting burden, thus affecting the quality and output of the product. If the high-carbon ferrochrome dust is pressed into the ball and then smelted again, the loss of Cr element is reduced, the hidden danger of environmental protection is eliminated, and the economic benefit of high-carbon ferrochrome production is improved.

Briquetting process of dust removal ash

According to the current national environmental protection policies and regulations on waste disposal, According to the composition, quantity, and distribution of high-carbon ferrochrome dust, the recovery and reuse scheme of high-carbon ferrochrome dust briquette is put forward. It is designed to realize the recovery and reuse of high-carbon ferrochrome dust briquettes through the processes of batching, mixing and rolling, briquetting the ball, drying, conveying, and flue gas waste heat recovery system.

Environmental analysis

After the implementation of the project, the high-carbon ferrochrome dust removal ash has been effectively treated, eliminating potential environmental protection hazards, realizing waste reuse, turning waste into treasure, and saving ore blending costs. Thereby realizing economic batching in a real sense, improving the recovery rate of mineral elements entering the furnace, and creating a precedent for physical utilization of high-carbon ferrochrome dust removal ash. Therefore, the implementation of the project is of great significance in protecting the environment and developing a circular economy.