Bearing Box of High-pressure Briquetting Machine

As a kind of briquetting equipment, the high-pressure briquetting machine continuously sends various dry and wet powder materials to the roller pressing area through the preloading device. Under the pressure of the roller pressing area, the dry and wet powder are pressed into briquettes, which are mainly used in coal, mining, metallurgy, refractory materials, building materials and other industries.

1. Structure and Motion Analysis of High Pressure Briquette Machine

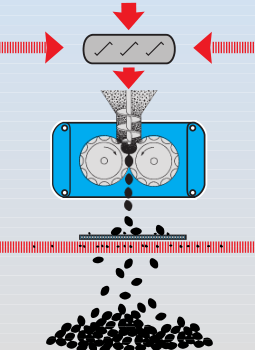

The high-pressure briquette machine is mainly composed of transmission system, feeding system, main frame, roller shaft part, belt conveyor and hydraulic system. The transmission system consists of main engine transmission, motor, coupling, reducer, ball slot alignment device coupling, etc. Power is transmitted into two working rolls respectively, i.e. Moving roller and fixed roller. The two rollers move in opposite directions and rotate synchronously.

Diagram of working principle. The integrated briquetting system.

The main frame is a frame-type composite structure, which consists of 8 square beams, including upper, lower, front, rear, left and right, and is positioned by cone pins. A fixed bearing seat and a movable bearing seat supported by an oil cylinder are installed in the frame of the main machine. The belt conveyor consists of electric roller, tail wheel assembly, idler belt, etc. It can be adjusted appropriately according to the needs of on-site process. The belt conveyor is placed inside the main engine and is of placement type. It does not need to be fixed by screws and adopts high-strength conveyor belts.

The hydraulic system consists of oil tank, oil pump, oil filter, overflow valve, one-way valve, accumulator and other components. Its main function is to automatically provide a stable pressure to the work roller and has the functions of energy storage and safe overflow.

The fixed roller group bearing box does not move in the main machine frame, one side is connected with the beam of the main machine frame, and the other side keeps a certain distance from the inner side of the moving roller group bearing box, which is the thickness of the adjustment pad, and the distance between the fixed roller group bearing box and the moving roller group bearing box depends on the diameter of the briquette. The other side of the moving bearing box keeps the required distance from the bearing box of the fixed roller group under the action of 9.5 x105N force of the upper and lower oil cylinders. The fixed end of the oil cylinder is positioned by the vertical beam at the moving end. The upper and lower movement of the bearing box depends on the limit of the crossbeam, the upper part of the crossbeam is equipped with a spiral feeding device, and the center line coincides with the center line of the roller nip. When the motor is started, the preloading screw continuously forces the material into the working area, and under the action of two working rollers, the material is pressed into briquettes.

2. Solution to the Deformation Problem of Bearing Box in Briquette Machine

A reinforcing plate and a variable point support plate are added between the cylinder piston and the moving bearing box. Through research and analysis, we know that the main reason why the roller of the moving bearing box is blocked is that the distance between the stress point of the bearing box on the cylinder side and the fulcrum of the adjusting frame is too large. Under the pressure of the oil cylinder, the side wall of the bearing box deforms, causing the outer ring of the bearing to be squeezed, thus causing the bearing clearance to change. Limited by the space of the entire rack, And the design of the cylinder cannot be changed, The following solutions are adopted: a 100mm reinforcement plate is added to the oil cylinder side of the movable bearing box, and two 200mmx50mmx5mm variable point support plates are added between the reinforcement plate and the bearing box to change the stress point of the oil cylinder piston on the side wall of the movable bearing box, so as to ensure that the bearing clearance is in a normal state when the briquette machine works, thus enabling the roller to operate normally.