Briquetting of Sponge Iron Powder

1. Objectives and indicators of the experiment

Sponge iron powder has small particle size, light weight, floating on the surface of molten steel and discharging outward with slag, with low recovery rate, and cannot be applied to industrial production. However, due to the long-term stacking of products, natural oxidation and waste are very serious. Therefore, after the sponge iron powder is pressed and molded, its oxidation resistance will be improved, its chemical composition will be stabilized, steelmaking problems such as floating and caking will be solved, and melting speed and recovery rate will be improved.

Determination of experimental index values. Sponge iron powder realizes briquette production, and the briquette index reaches the following standards: the falling strength of each block is ≥ 5 times/meter, and TFe is ≥ 87%.

2. Raw materials and equipment experiment

Raw material: sponge iron powder.

Binder: Sodium silicate.

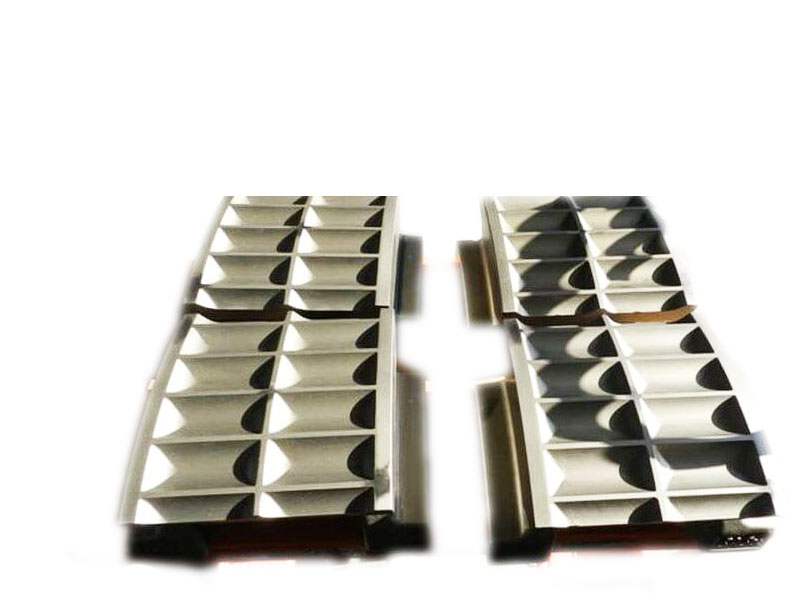

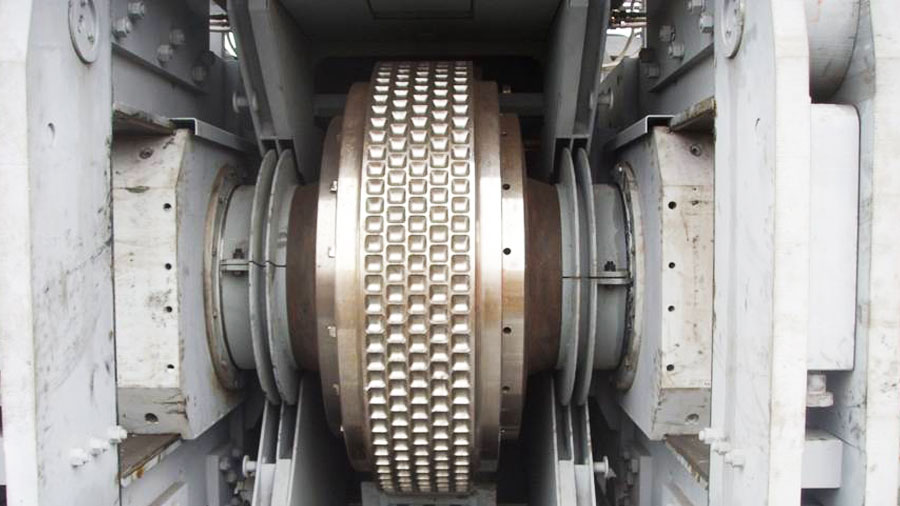

Experimental equipment: Sponge iron cold pressing machine is used, the pressure is 1200KN, and the total power of the motor is 30KW.

3. Experimental method

Ingredients: Take 100kg of sponge iron powder each time, and mix the ingredients with 53% sodium silicate (0%, 1.0%, 1.5%, 2.0%, 2.5%).

Mixing: Use a mixer or a strong mixer to stir the prepared materials for 3-5min to a uniform state.

Feeding: Manual feeding is adopted. After the mixed materials are packed in bags, they are manually poured into the receiving tank of the briquetting machine.

Briquetting operation: operate the briquetting machine to produce sponge iron powder briquetting.

Drying: Take 20 briquettes each time and put them into a drying box for constant temperature drying at 120 ℃ and drying for 4 hours.

Falling strength detection: 10 briquettes are taken for detection at a time, and the falling height is 1 meter, so as to detect the falling strength.

Test: Sponge iron powder, wet briquette, dried briquette and naturally dried briquette were tested respectively, and the indexes of TFe, MFe and FeO were measured.

4. Experimental results

4.1 Selection of binder proportion

Different binder ratios can be seen from the experimental results of briquetting after mixing in mortar mixer. The binder ratio is ≥ 1.0%, and the falling strength of briquetting meets the requirements. In order to ensure the quality of briquetting, the binder ratio is 1.0%-1.5% in production.

4.2 Selection of mixed equipment

It can be seen from the mixing comparison experimental results of mortar mixer and strong mixer that both strong mixer and mortar mixer can meet the requirements, and the mixing effect of strong mixer is better than that of mortar mixer.

4.3 Drying system

Among the effects of different drying systems on the briquette strength, the wet briquette strength is low, and the briquette strength gradually increases with the extension of natural drying days. The briquette strength can reach the highest strength after 5 days of natural drying, and then the briquette strength will not increase with the extension of natural drying days.

4.4 Influence of drying system on chemical indexes of briquettes

With the continuation of the drying process, the TFe content of the briquette gradually decreases. After 5 days of natural drying, the decreasing speed starts to slow down, and the briquette strength reaches the maximum value at this time. This shows that the wet briquette has basically dried out after 5 days, the oxidation reaction inside the briquette has basically ended, and the TFe index is stable.

From the experimental results, the TFe index of the dried compact is higher than that of the natural dried compact, because the compact shortens the contact reaction time between moisture and MFe during drying. However, natural drying, slow water overflow rate in sodium silicate and long oxidation time of MFe reduce TFe index. However, the influence is generally about 0.5%, which can meet the target requirements. It is feasible to choose natural drying.