Experimental Research Regarding the Effect of Mineral Aggregates on the Wear of Mixing Blades of Concrete Mixers (1)

1. Introduction

The loadings of the mixing elements of the mixer but also of its tank armor are determined by the complex phenomena of abrasive–erosive–corrosive wear due to very aggressive simultaneous actions determined by the friction of the mineral aggregates on the active surfaces of the mixer, the impact of the aggregate particles on the active surfaces of the mixer, and the corrosive action of cement in combination with water.

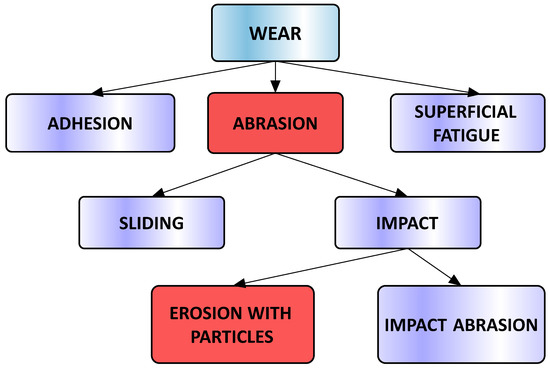

The wear of the component elements of concrete mixers and the removal of material due to this phenomenon can manifest in various forms, such as adhesion, abrasion, and surface fatigue (Figure 1).

Figure 1. Wear phenomena specific to concrete mixers.

According to the results from the scientific papers, the level of mechanical stress in mixers is strongly influenced by factors such as the angle of impact, the impact velocity, and the hardness of the wet components within the mixer.

The article provides an extensive examination of the key factors influencing wear on impellers in solid–liquid slurry applications, as well as strategies for minimizing the wear. The critical parameters explored include the following aspects: the chemical environment, hardness of solids, density of solids, percent solids, shape of solids, fluid regime (ranging from turbulent to transitional or laminar), hardness of the mixer's wetted parts, hydraulic efficiency of the impeller (including kinetic energy dissipation rates near the impeller blades), impact velocity, and impact frequency.

Sapate examined the impact of erodent-particle hardness on the velocity exponent of certain weld deposited alloys and focused on three steels and two alloy cast irons, with bulk hardness ranging from 300 to 800 HV. The erodent particles used in the tests had hardness values ranging from 400 to 1875 HV. Erosion tests were conducted using cement clinker, blast-furnace sinter, silica sand, and alumina particles with sizes ranging from 125 to 150 µm. The impingement angles tested were 30° and 90°, and the impingement velocities varied from 25 to 120 m/sec. Regardless of the erodent-particle hardness and impingement angle, an increasing trend was observed between the velocity exponent and the hardness of the alloys. Similarly, the velocity exponent increased with higher erodent-particle hardness, independent of the impingement angle and alloy hardness.

The main findings of indicate that velocity exponents derived for “erosion-dominated” conditions are similar to those observed for “ductile” erosive processes. However, in “corrosion-dominated” conditions, the velocity exponents are significantly lower compared to those found in “brittle” erosive processes at room temperature. In cases of “erosion–corrosion-dominated” conditions, the velocity exponents exhibit strong dependence on temperature, alloy composition, and the relationship between velocity and particle flux.

The objective of study was to design and construct a wear-testing rig specifically for a water pump impeller in order to identify a parameter that can effectively determine the wear rates of the slurry pump impeller. The wear environment used was a mixture of solid particles and water. The findings revealed that erosion was the predominant type of wear observed in the experiment and the weight loss of the impeller was attributed to material removal caused by erosive wear.

Studies investigated the type and level of mechanical stresses corresponding to the most exposed parts of the mixers, namely the blades and the arms.

Another significant challenge for the concrete mixers is the abrasive wear that can produce in both wet and dry conditions. Studies were conducted to determine the stress states in the arms and mixer blades subjected to abrasive wear.

Jungedal investigated the wear resistance (measuring sliding wear resistance and impact wear) of more than 30 types of steel, simulating, through an experimental stand, the concrete mixer with crushed granite mainly. The wear losses were evaluated by conducting weight measurements before, during, and after testing. A correlation was identified between hardness and wear resistance, with higher hardness levels demonstrating improved resistance to wear in the specific application under investigation. Furthermore, it was observed that the shape and degradation of abrasives had an impact on the wear rate.

The scientific literature in primarily focused on the wear characteristics of concrete mixers, specifically analyzing the wear behavior of blades and evaluating the performance of new blade designs using a combination of numerical simulations, experimental tests, and 3D optical scanning techniques. These studies demonstrate that the new blade designs significantly reduce wear, increase durability, improve mixing efficiency, and lower maintenance costs and time.

In paper, an evaluation was conducted on pastes and mortars mixed for various durations and different numbers of mixer revolutions. The focus was on assessing early-age properties, such as time-dependent ion concentration in the solution, flowability, setting time, and chemical shrinkage. The findings reveal that these early-age characteristics of laboratory-mixed pastes and mortars are affected by the duration of mixing and the number of mixer revolutions. Also, Prasittisopin and Trejo [23] examined the impact of mixing time and the number of mixer revolutions on the hardened properties of laboratory-produced mortars. The results demonstrate that longer mixing times are associated with higher compressive strengths after one day but lower strengths after 28 days. Additionally, increasing the number of mixer revolutions can lead to higher porosity, resulting in reduced strength. A similar study presents the findings regarding the influence of mixing time and number of mixer revolutions on the properties of laboratory-produced pastes and mortars containing 20% and 50% fly ash, demonstrating that as the mixing time and number of mixer revolutions increase, the mixtures incorporating fly ash as a replacement material exhibit enhanced fresh and hardened properties.

The research in focuses on the distinct aspects of a new industrial process and its impact on engineering requirements, particularly the mechanical and microstructural characteristics of castings. The study also highlights the essential directions for further exploration of the potential of this emerging technology in producing high-quality castings. To assess the effects of ablation sand casting on the AlSi7Mg alloy impeller, investigations were conducted on various process parameters, such as binder ratio, AFS number, and pouring temperature. The evaluation includes dimensional accuracy, hardness, and ultimate tensile strength as key factors.

The equipment used in concrete production is designed to withstand the hard operational conditions imposed by the corrosive nature of the water–cement dust mixture and the abrasive properties of mineral aggregates. The active components of this equipment (especially in the case of concrete mixers) often involve costly materials and specialized manufacturing technologies. Notably, the walls, mixing blades, and arms of these mixers require special maintenance due to the fact that they are made of special materials. The maintenance activities for the entire plant are influenced by the replacement intervals of these components. Taking into account the challenges mentioned above, this research aims to provide recommendations for selecting appropriate materials for manufacturing mixing blades, based on their tribological characteristics, using both analytical methods and experimental investigations conducted on a stand designed to reproduce the mixers' functioning conditions.

2. Materials and Methods

The experimental analysis focused on the constructive–functional and material characteristics of a double-shaft mixer used in the concrete manufacturing facility operated by STRABENBAU LOGISTIC SRL, Blejoi, Romania.

The experimental research was conducted to evaluate the wear behavior of the materials used in the manufacture of mixer blades, using an experimental stand to reproduce, in laboratory conditions, the concrete mixer operation.

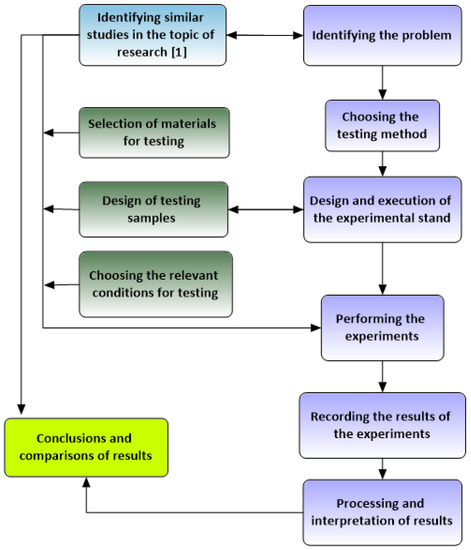

Figure 2 shows the steps taken to perform the present study, including both experimental and analytical methods of analysis.

Figure 2. The steps of the research program.

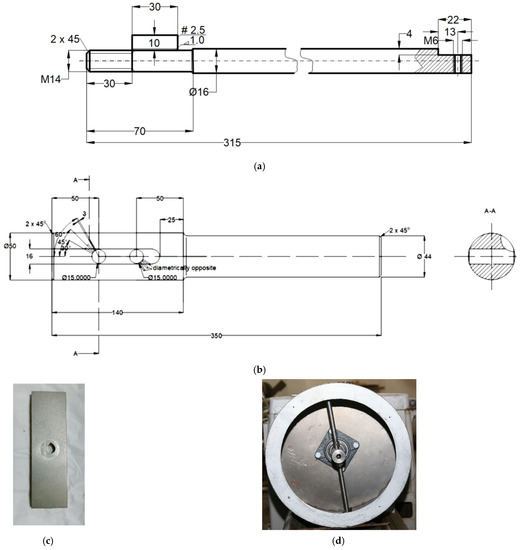

The experimental stand was designed to reproduce, on a scale of 1:2, the real mixer shaft in the concrete mixing plant. The stand consisted of a cylindrical bowl with a window at the top for feeding the mineral aggregates but also to allow the mixer arms to be fitted/removed. A shaft (in a bearing), with two mixing arms, was mounted inside the bowl, and the position of the shaft could be changed, relative to the shaft axis, after a fixed generator (Figure 3). At the ends, the two mixing arms were fitted with parallelepiped mixing blades (79 mm × 24 mm × 4 mm), which could be removed and replaced. This allowed the use of blades (as test samples) made of different materials.

Figure 3. Components of the experimental stand: (a) drawing execution mixer arm, (b) drawing execution drive shaft, (c) sample blade, and (d) drum with the mentioned elements.

The cast-iron samples (the mixing blades of the experimental stand) were obtained by cutting with a water jet to avoid the thermal influence of the material characteristics (Figure 4). The faces of the blades were processed, finally, by grinding on a plane–peripheral machine.

Figure 4. Cast-iron sample preparation on the water-jet-cutting machine: (a) raw sample, (b) sampling by thickness cutting—first face, (c) sampling by thickness cutting—second face, (d) drilling the specimen in the central area at 13 mm from the longest dimension, and (e) cutting at 24 mm dimension.

For the tests, three types of cast-iron materials alloyed with different Cr contents (samples no. 1, no. 2, and no. 3 with, respectively, 4% Cr, 9% Cr, and 25% Cr) were chosen.

2.1. Chemical Composition and Hardness of the Studied Samples

Table 1 presents the chemical compositions of the three cast-iron samples, determined by the optical-emission-spectroscopy method in the Mechanical Engineering Department Laboratory at the Petroleum–Gas University of Ploiești.

Table 1. The chemical composition of cast-iron samples.

| Sample | Chemical Composition, % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | P | S | Cr | Mn | Fe | Ni | Mo | |

| 1 | 3.28 | 0.76 | 0.07 | 0.03 | 3.83 | 1.10 | 89.86 | 0.89 | 0.20 |

| 2 | 3.72 | 0.74 | 0.02 | 0.04 | 25.65 | 0.87 | 68.19 | 0.040 | 0.35 |

| 3 | 3.08 | 0.96 | 0.04 | 0.03 | 9.77 | 1.14 | 84.12 | 0.35 | 0.49 |

The hardness characteristics of the three types of material used in the tests (hypoeutectic white cast iron) depend on the content of Cr and are shown in Table 2.

Table 2. Hardness values for samples subjected to wear tests at the beginning and end of the test program.

| Value of Tilt-Angle Blade Relative to the Axis of Rotation, (Degrees) | Blade—Cast Iron 1 HV0.2 | Blade—Cast Iron 2 HV0.2 | Blade—Cast Iron 3 HV0.2 | |||

|---|---|---|---|---|---|---|

| Unworn Sample | Worn Sample | Unworn Sample | Worn Sample | Unworn Sample | Worn Sample | |

| 30 | 464.654, value from [1] | 1191 | 1228.505, value from | 911 | 632.9904, value from [1] | 676.5 |

| 45 | 1237 | 1029 | 936.5 | |||

| 60 | 1320 | 1260.5 | 1177 | |||

Figure 5 presents the microstructural characteristics of the three sample materials.

Figure 5. The microstructural details of the analyzed materials: (a) blade no. 1, (b) blade no. 2, and (c) blade no. 3.

It can be observed that the microstructure of the three samples presents distinctive characteristics specific to white hypoeutectic cast irons, with different forms of hard constituents, which vary based on the chromium (Cr) content.

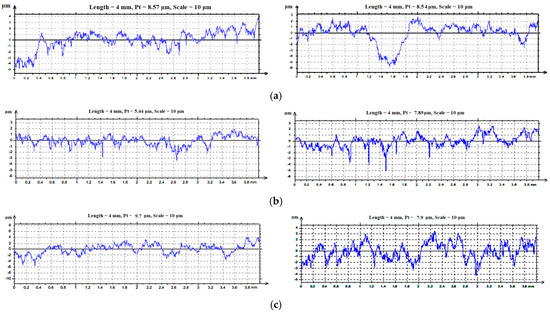

2.2. Determination of Microgeometrical Parameters of the Samples

The microgeometrical characteristics of the sample surfaces were measured with the SURTRONIC 3+ profilometer (Figure 6) and are presented in Table 3 and Figure 7.

Figure 6. The SURTRONIC 3+ profilometer used for the measurement process.

Figure 7. The profile curves for contact surfaces of samples: (a) 1A, 1B; (b) 2A, 2B; and (c) 3A, 3B.

Table 3. Roughness values of cast-iron samples.

| Sample/Sample Face | 1A | 1B | 2A | 2B | 3A | 3B |

|---|---|---|---|---|---|---|

| Roughness value Ra, μm | 0.555 | 0.569 | 0.452 | 0.528 | 0.810 | 0.805 |

2.3. Description of the Experimental Method

The test program included, for each type of material (cast iron), 3 sets of tests consisting of subjecting the specimens to a wear process generated by the friction between the active surfaces of the blades, rotating inside the drum, and the aggregate introduced into the mixing space. In this phase of the research tests, dry aggregates were used. According to SR EN 12620-A1:2008, the dry aggregates have the following characteristics: granulometric class 4–8 mm, content of fine particles 1.5%, chloride content < 0.0025%, shape index SI 15, and water absorption WA 24.

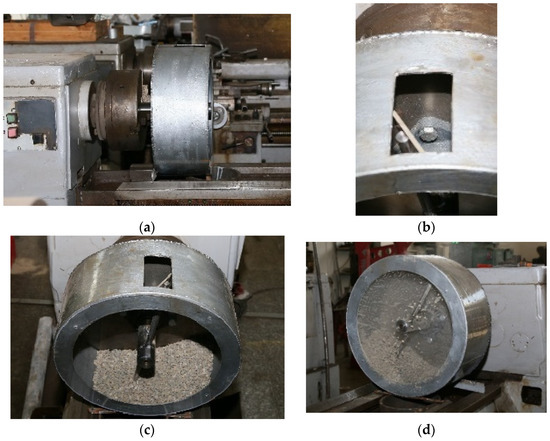

The rotation of the mixing arms was determined by the main motor of a universal lathe, type SN 400. The entire experimental stand was mounted on the normal lathe (Figure 8).

Figure 8. Experimental stand: (a) front view, (b) window for mounting arms, (c) 5 kg of mineral aggregates, and (d) rotational motion.

The wear of the cast-iron samples (blades) was determined gravimetrically by weighing them at different time intervals using an analytical balance, type KERN ALJ, with an accuracy of 10−4 g.

Before each weighing, the cast-iron samples were prepared by washing with methyl ethyl ketone (MEK), wiping with a solvent-resistant microfiber cloth, and drying in warm air. For good reproducibility of the tests, the quantity of aggregates was replaced before each cycle, respecting the particle-size class and the mass of mineral material. This ensured the same testing environment conditions for each stage of the experimental program.

In order to characterize as fully as possible the behavior of the studied materials under operating conditions, the experimental program involved three sets of tests, for each type of material, characterized by different angles of inclination of the active face of the blade relative to the shaft axis (30, 45, and 60 degrees).

The aggregate material used in the tests was crushed stone with a grain size of 4–8 mm. The quantity of stone used in each test cycle was 5 kg. The rotating speed of the main shaft during all tests was 40 rpm.

2.4. Theoretical Method Used to Confirm the Experimental Results

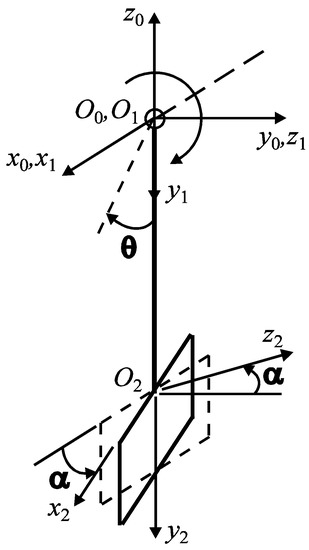

In order to evaluate, exclusively, the effect of the friction of the aggregate particles on the mixing blades, an analytical model was created. Therefore, this research studied the influence on the ratio between the frictional force (manifested on the surface of the mixing blade) and the weight of the aggregate material from the mixer bowl—of the angle of inclination of the active face of the blade, relative to the shaft axis α—as presented in Figure 9.

Figure 9. Schematic representation of the mixing arm and the blade.

The frictional force 𝐹𝑓 is determined with the relation:

where μ is the sliding frictional coefficient between the aggregate material and the blade and N is the normal reaction to the blade surface, corresponding to its loading with the aggregate material.

If we denote by G the weight of the aggregate material that loads the blade, then 𝑁=𝐺𝑧2, where 𝐺𝑧2 is the component of the weight G along the axis 𝑂2𝑧2.

The projections of the weight G on the axes of the coordinate system 𝑂2𝑥2𝑦2𝑧2, grouped in the vector 𝐺(2), are determined with the relation

where 𝐺(0) is the vector containing the projections of the weight G on the axes of the fixed coordinate system 𝑂0𝑥0𝑦0𝑧0(𝐺(0)=[00−𝐺]T) and 2𝑅0 is the rotation matrix corresponding to the relative orientation between the coordinate systems 𝑂2𝑥2𝑦2𝑧2 and 𝑂0𝑥0𝑦0𝑧0 during the operation

where, as can be seen in Figure 9,