High Pressure Briquetting of Lignite After Drying

1. Structure of Large Briquette Machine

The large briquette machine consists of transmission motor, synchronous gear reducer, preloading device, main machine device, hydraulic system, belt conveyor and electronic control. Among them, the synchronous structure adopted by the transmission system makes the main engine transmission realize good design,manufacture, use and maintenance. The hydraulic device adopts the structure of small cylinder body and large tension force, thus realizing the purpose of reducing the quality of the whole briquette machine and reducing the consumption of steel. The briquette machine's roller adopts a combined structure, which realizes that vulnerable spare parts can be replaced on site, thus reducing the loss caused by the shutdown of the production line.

2. Working Principles

When working, the materials pass through the feeder from the intermediate silo, enter the feeding port of the briquette machine quantitatively and evenly, and reach the preloading feeder of the main machine. So that a stable material level is maintained in the preloading feeding device. By the preloading screw in the preloading feeder. Forcibly press the material into the middle of the roller, the material is pre-compressed and gas is removed and forced to be transported to the arc grooves of the two ball pressing rollers for deduction. The spherical sockets with the same shape are evenly distributed on the surfaces of the two ball pressing rollers. Through the meshing transmission of the synchronous gear reducer, the two ball pressing rollers are operated at the same speed and opposite to each other, and the materials transported to the arc notch are bitten into the notch and forcibly compressed. As the rollers continue to rotate, the pressed and formed materials fall out of the ball socket under the action of their own elasticity and gravity when exceeding the center line, thus completing the process of pressing into pellets.

3. Lignite Dried and Formed under High Pressure without Additive

3.1 Mechanism of high pressure briquetting

Through drying, the total moisture content of lignite can be degraded to less than 10%, but the capillary structure in lignite has not been damaged, containing more than 35% asphaltene, and the volatilization of humic acid and organic matter has hardly changed. By applying high pressure to it, the capillaries of lignite are broken, deformed and crushed, and the tiny particles of lignite are re-arranged and concentrated. The organic matter of volatile in lignite changes and assembles again under high pressure, which also promotes the rearrangement and accumulation of tiny particles in lignite. Finally, powdery dry lignite with a density of 0.65g/cm3 was pressed under high pressure into pellets with a density of more than 1.50g/cm3, a strength of more than 500N, and a bright surface.

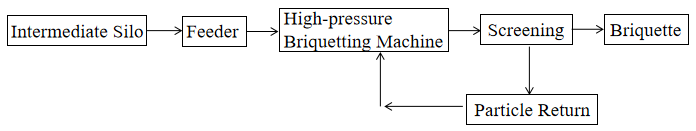

3.2 The flow chart of the process

The dried lignite is screened, and the screen less than 6mm is blanked into the intermediate bin, fed to the large ball press quantitatively and evenly through the feeder, and then fed to the briquette machine for molding. After screening, the granules are returned to the briquette machine for further molding, and the finished pellets are transported for export.

During the forming process of lignite, the gel structure and pore system of lignite are irreversibly damaged by physical actions such as high pressure or shearing, because the coal rank of the sample is essentially changed, and the coalification degree is also increased.

3.3 Equipment for high pressure briquetting

The machines and equipment for drying lignite with a output of 50t/h mainly include conveyor, intermediate bin, quantitative feeder, large ball press, screening machine, finished product conveyor, particle return conveyor, electronic control system, chute, bracket, etc.

4. Conclusion

As lignite has the defects of high moisture content, high ash content, low calorific value, easy weathering and spontaneous combustion, it is necessary to dry and shape lignite.The high-pressure briquetting process flow after lignite drying has simple equipment configuration and low operation cost, which conforms to the lignite drying and quality improvement industry.