Forming of manganese ore powder and manganese metal

The alloying elements in steel are obtained by adding ferroalloy or elemental metal to the liquid steel in the process of steelmaking, such as ferrosilicon, ferromanganese, nickel iron, chromium iron, etc. Different iron and steel enterprises have different processes, this article only discusses the addition of manganese in steel production.

According to our current practice, manganese can be added in the following ways:

Ferromanganese or ferromanganese, or MnFe, which is used in most steel mills.

Manganese metal, that is, Mn, the content of manganese metal at least 95% or above, a small number of large iron and steel enterprises will use manganese metal.

Manganese ore ball directly joined.

No matter which form the manganese element is added. In order to reduce the loss of combustion, it is usually added in the shape of a ball or block with a certain geometric size.

1. Ferromanganese

Ferromanganese is made from manganese ore powder through reduction, usually there are two kinds of process, the mainstream process is, manganese ore fine powder through pelletizing sintering and coke together into the ore furnace for reduction, that is, the so-called external carbon process. Another is the direct reduction process, manganese ore powder and the appropriate coal powder, may also be added to some desulfurizer mixed pressure ball, and then into the reduction furnace for direct reduction, the common kiln furnace has a hot furnace also has microwave reduction furnace, this is the so-called 'internal carbon' process.

Not all ferromanganese are suitable block, there are also small particles of ferromanganese. It can be either directly used after pressing the ball molding, or directly returned to the ferromanganese reduction furnace for reduction.

2. Elemental metal manganese briquette

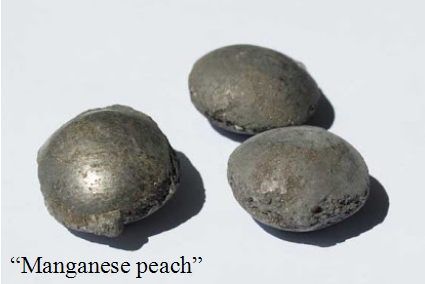

We also call it 'manganese peach'or 'manganese pillow',because of its shape like a peach or pillow.

Initially, manganese briquette is used as an additive in the smelting of aluminum-manganese alloy and aluminum-magnesium alloy. At present, baosteel and baowu steel in Europe, America, India, South Korea and China begin to replace some electrolytic metallic manganese with manganese briquette, making it the main raw material for the smelting of high-quality steel and high-manganese alloy.

The raw material of manganese peach is electrolytic manganese metal, which is obtained by adding some binder mixture, pressing balls, drying, packaging and other processes.

3. Manganese ore ball

In practice, iron and steel enterprises directly use manganese ore ball to replace ferromanganese to obtain manganese element, which is established from the theory of ferroalloy thermodynamics.

3.1 The high-valent oxides in manganese ore powder are decomposed into low-price manganese oxide at high temperature.

480℃: MnO2 → Mn2O3

2MnO2 → Mn3 O4+ 1/2O2

927℃: 3Mn2O3 → 2 Mn3 O4+O2

1177℃:Mn3 O4 → 3MnO+O2

Low valent manganese oxide reacts with carbon to reduce mangansed mateal:

MnO+C → Mn+CO

3.2 Use of manganese ore ball in steelmaking

The temperature of liquid steel in steelmaking, the alkalinity of slag and the ladle bottom argon blowing process after steel are similar to the smelting process of ferromanganese. In ladle or LF electric furnace, the manganese element in manganese ore powder is reduced from the oxide into liquid steel to replace the addition of ferromanganese.

The process needs to be further practiced and optimized, and the process operation of steelmaking and the addition of slag materials need to be adjusted.

Some data show that adding manganese ore pellets into steelmaking can not only reduce energy consumption and environmental pollution in the smelting process of ferroalloy, but also reduce the cost of steelmaking, which has great social significance and economic benefits.

The above several manganese elements are added in the steelmaking process in the form of more or less involved in the ball pressing process. The basic ball pressing process is as follows:

Dosing→Mixing→Briquetting→Drying

(Note:Drying is not necessary, please refer to the specific process.)