Technology of Coal-based Direct Reduction Iron(3)——DRYIRON method

1. Simple introduction

GLOBA (Former MR&E Company) was the technical development arm of the rapid heating process in midland-ross in 1960 and became an independent company in 1985.

GLOBA has a strong track record in the DRYIRON process and holds two patents in the DRYIRON process:

① Using waste syrup as binder, the mixture of iron oxide powder and toner is pressed by dry method with briquette equipment and then directly loaded into RHF furnace, eliminating the drying process of pellet.

② Charge loading method using special vibration transmission device.

This process can achieve DRI with over 90% metallization rate, which is an ideal coal-based direct reduction process. Its operation has great flexibility and the operation control of equipment is very easy. In 1999, The Steel division of Nippon Steel introduced RHF DRYIRON method from MR&E Company in the United States and obtained the qualification of agent marketing. This is the basis for the development of FASTMET method in Japan.

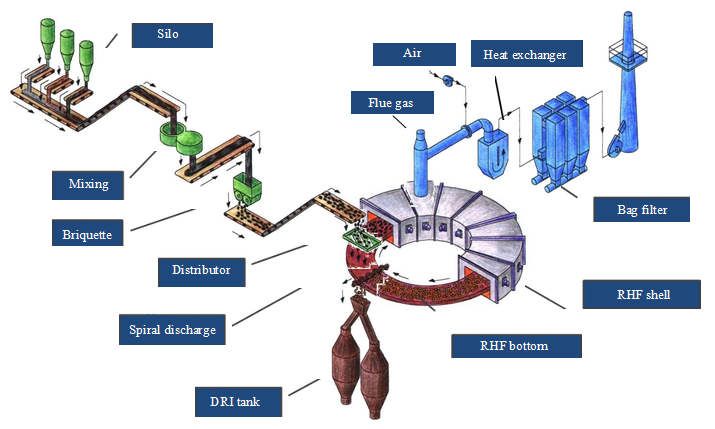

2. The basic process

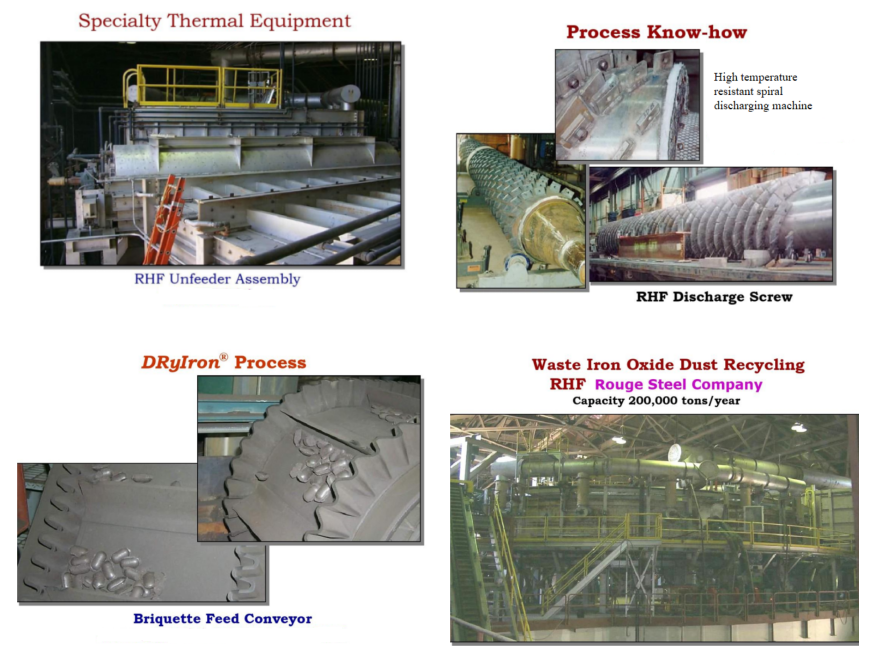

3. Main equipment pictures

4. Operating cost of DRI process using iron powder as raw material in USA

Item | Unit | Consumption | The unit price ($) | Amount of ($/t) |

Raw material | ||||

Iron Concentrate | kg | 1335 | 0.022 | 29.37 |

Coal | kg | 410 | 0.05 | 20.5 |

Bentonite | kg | 5 | 0.065 | 0.33 |

Organic binder | kg | 5 | 1 | 5 |

Subtotal | 55.2 | |||

Energy | ||||

electricity | KW.h | 65 | 0.035 | 2.28 |

Natural gas | m³(STP) | 60 | 0.1 | 6 |

Nitrogen | m³(STP) | 10 | 0.04 | 0.4 |

Water | t | 0.3 | 0.033 | 0.01 |

Subtotal | 8.69 | |||

Other | ||||

consumables | 1 | |||

Maintenance and spare parts | 1 | |||

Total | 65.89 | |||

Note: | ||||