- KAIZHENG

- CHINA

- To be confirmed

- Sufficient

Main features:

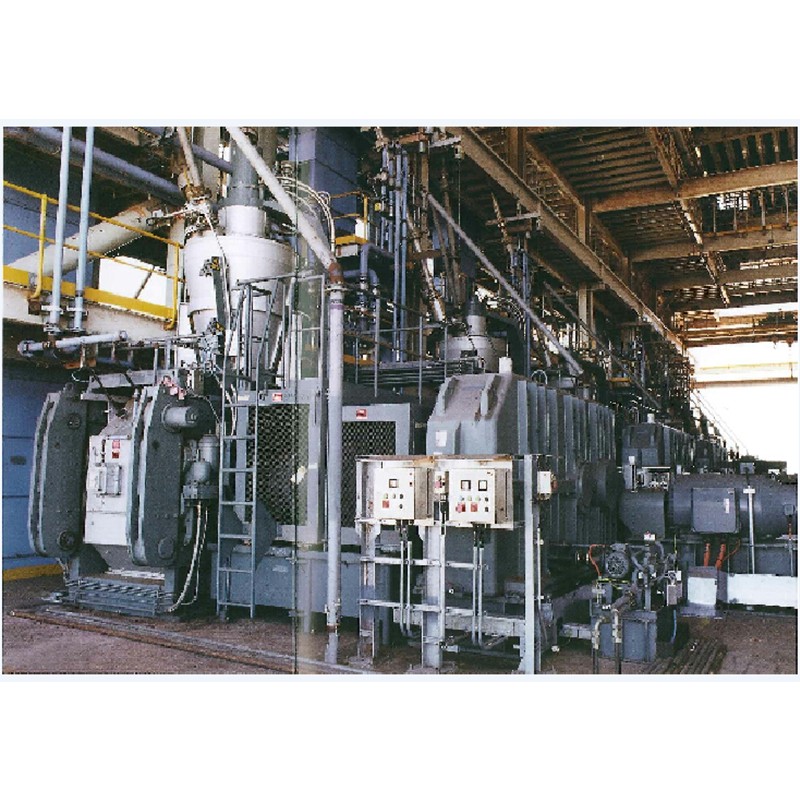

The transmission system: Motor--Elastic coupling (belt drive)--Twin-shaft reducer--Gear coupling--two rollers.

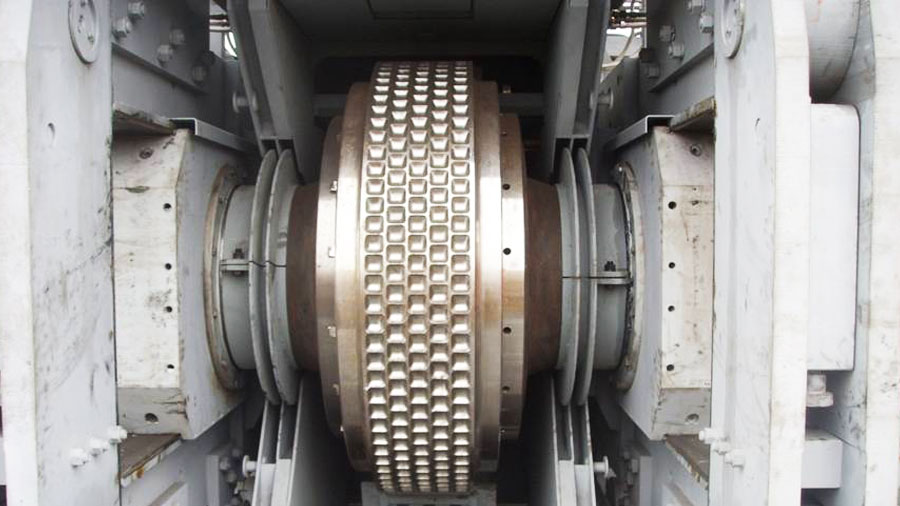

Roller structure: Mosaic structure with laminated roll sleeve.

Roller material: High quality bearing steel, cold working die steel and martensite stainless steel (suitable for acid materials)

Bearing assembly: return sleeve structure equipped with special tools for disassembling and assembling.

Knowlege and experiance are need for the selection of roller material.

Cooling system ,in particular, the selection of cooling area and the control of cooling cycle are the core technique. The cooling media can be soften water or heat transfer oil.

Note: Specific crushing equipments are installed regarding to certain materials, for seperating the likely adhesive briquettes.

Applied material: Composite iron coke, carbon pellet, hot briquetting coke, sponge iron.

Difference of cold briquetting and hot briquetting:

Cold briquetting | Hot briquetting | |||

Temperature | Environment temperature Up to 50℃ | ≤250℃ | ≤450℃ | ≤850℃ |

Cooling system | None | Yes | Strong cooling | Severe cooling |

Roller material | Bearing steel/tool steel | Tool steel/die steel | High temperature bearing steel | High-speed steel |

Roller structure | Hot assembly/Hub-shaft connection/piecewise inlay | Piecewise inlay | ||

Material | Cold powder | Low temperature forming of iron coke | Hot pressing coke,shaped coke | Sponge iron |

Main features:

The transmission system: Motor--Elastic coupling (belt drive)--Twin-shaft reducer--Gear coupling--two rollers.

Roller structure: Mosaic structure with laminated roll sleeve.

Roller material: High quality bearing steel, cold working die steel and martensite stainless steel (suitable for acid materials)

Bearing assembly: return sleeve structure equipped with special tools for disassembling and assembling.

Knowlege and experiance are need for the selection of roller material.

Cooling system ,in particular, the selection of cooling area and the control of cooling cycle are the core technique. The cooling media can be soften water or heat transfer oil.

Note: Specific crushing equipments are installed regarding to certain materials, for seperating the likely adhesive briquettes.