granulator

-

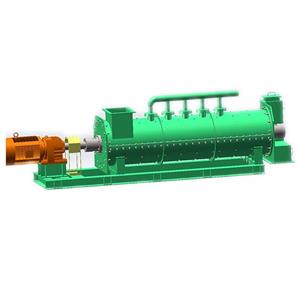

Pin Mixer Granulator

Pin mixer is used for micro mixing and granulation with suitable materials. Mixing and granulation are done in the same unit. Powder and liquid materials are converted into small pellets by means of high-speed rotors and pin shafts. According to different process, the liquid can be water,binder, oil or surfactant. Whereas, the powder can be ceramsite sand, carbon black, cement kiln dust, pigments, coal dust, pesticides, arc furnace dust collection ash, limestone powder, graphite, coke, petroleum coke powder and silica fume, bauxite, etc. According to user's requirements and operating conditions, this series of equipment has a variety of configurations. Model MP--is the continuous operation mixing granulator, and model MPJ- is the intermittent operation mixing granulator. Compared with the continuous mixing granulator, the product qualification rate of intermittent operation equipment is higher, reaching more than 70%, but the single-machine processing capacity is lower.

Email Details -

Hot

Compacting and Granulating Machine

The ultimate goal of compaction is to convert the powder into particles of various shapes and sizes. In general, it is not necessary to add adhesive, and the product is compacted by applying a certain extrusion pressure to the material. The pressure level depends on the material and it will be finally processed into certain thickness. Kaizheng offers compact and complete turnkey systems (including electrical interlocks and interface controls) that integrate system molding units to meet your specific needs.

Email Details