- : KAIZHENG

- : CHINA

- : To be confirmed

- : Sufficient

Briquette machine is the main equipement with the applied powder material forming technology. Its apllications can be seen in a wide range of industries. Briquetting, as a stage of the process, it could be aimed for minimizing the need of dust removal and ventilate, it could be an end-product for selling.

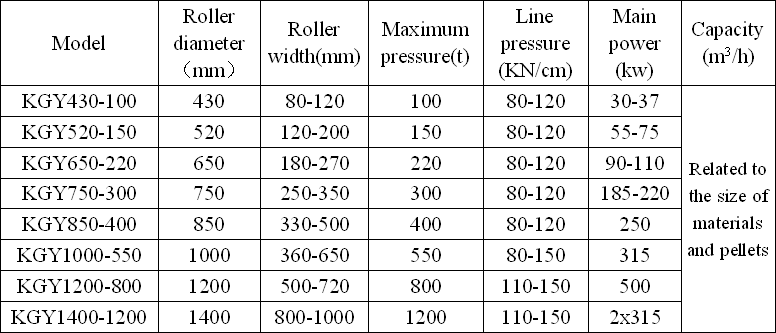

We consider it as high pressure briquetting machine, once its line pressure is 50-120KN/cm. The common ones are 80KN/cm,110KN/cm,120KN/cm and 150KN/cm.

High Pressure Briquette Machine Main features:

The transmission system: motor -- elastic coupling (belt drive) -- double outlet reducer -- gear coupling -- two rollers.

Roller structures: hot-mounted structure, detachable expansion and tightening sleeve, and Mosaic structure with the segmented roller sleeve.

Roller materials: High quality bearing steel, cold working die steel and martensite stainless steel (suitable for acid materials)

Bearing assembly: return sleeve structure, equipped with special tools for disassembly and assembly.

Prepressing screw: It is one of the core technologies. According to the material characteristic (mainly refers to the fluidity, the abrasiveness, the granularity), it is specially designed with cleaning and extrusion function. Variable pitch spiral is designed for hard molding materials.

High Pressure Briquette Machine Applied materials:

Minerals: bauxite, limestone, aluminum ash, dolomite, gypsum, clay, magnesium oxide, fluorite, pigment, laterite nickel ore, vanadium pentoxide, zirconium hydroxide, zirconium zirconate...

Metallic minerals: chromium nickel iron, manganese metal powder, silicon manganese alloy, molybdenum oxide, chromium ore powder, manganese ore powder, chromium iron, nickel iron...

Cold pressing block of direct reducing iron.

All kinds of dust removal ash.(electric furnace dust removal ash, converter dust removal ash, blast furnace dust removal ash, sintering powder, coke powder...)

Coal, black carbon, graphite, charcoal...

Iron coke, carbon containing pellets...

High Pressure Briquette Machine principle:

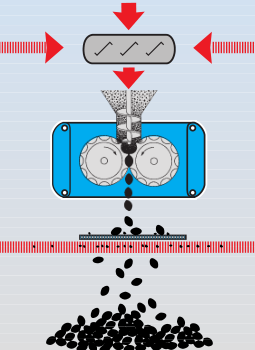

The powder material is compressed between a pair of rotating rollers, the one is movable and it provides pressure through a hydraulic system. It might be single material or mixed material, even binder is needed sometimes.

High Pressure Briquette Machine Process:

Different m:aterials have related briquetting performance, which requires a reasonable and optimized machine. It is also significant in taking the quality of final product into consideration.

The briquetting performance of a material depends on itself, such as the fineness, grain size, water content, composition, etc., which usually needs to be determined by testing.

Not all materials have sphericity, if the bonding force between the material particles is low, a suitable adhesive is necessary. According to the physical properties of the material and the purpose of the final briquette, the choice of binder needs to be made based on its bonding performance and use cost.Various adhesives such as starch, bentonite, asphalt, quicklime, cement, water, flour, lignosulfonate, molasses, polymers, resins, sodium silicate and new composite binders are for specific purposes.

The key process of briquetting machine is "continuous quantification", which usually requires continuous batching, mixing and subsequent drying links (see the batching and mixing links in the sample booklet).

In practice, Kaizheng has accumulated considerable experience with a complete turnkey system,including electrical interlock and interface control,that integrates system molding units to meet your specific needs.

Note: The process varies relating to different materials and applications.

High Pressure Briquette Machine Technical parameters:

Note: Our company has the briquetting test machine, so we can experiment with client's material, and determine its briquette performance and find out reasonable line pressure ratio.